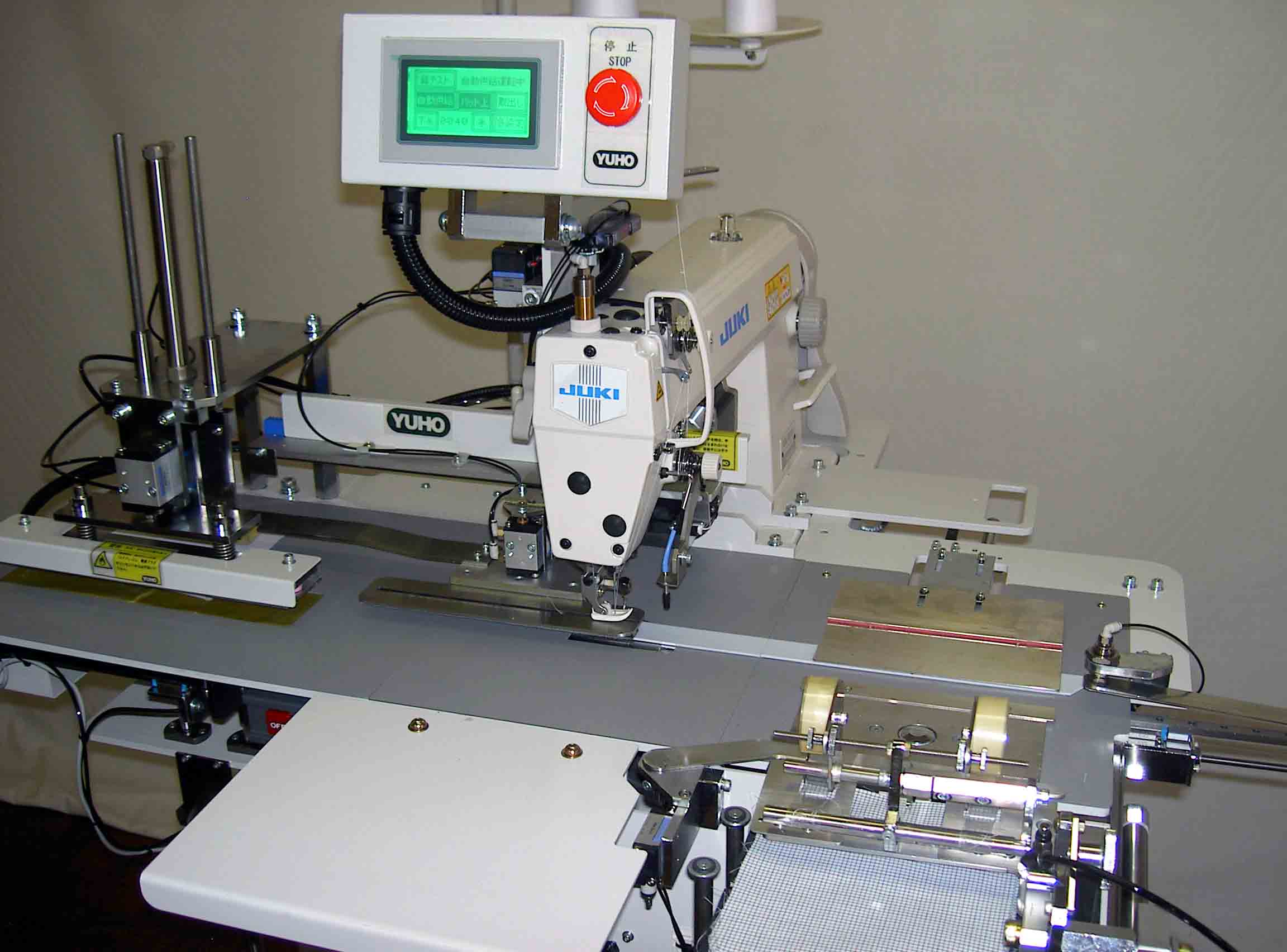

‘@ SHIRT POCKET-TOP HEMMER@U-3007-E@‘

‘@ AUTO SHIRT POCKET-TOP HEMMER@U-3007-E/AUT@‘

|

AUTO POCKET-TOP 3-FOLD HEMMING ROBOT !!

FULL-AUTOMATED POCKET-TOP 3-FOLD HEMMING IS NOW DEBUT ON !!

BIAS POCKET-TOP 3-FOLD HEMMING IS ALSO ALLOWED AUTOMATICALLY !!

AUTO HEAT PRESSING IS ALSO AVAILABLE AFTER 3-FOLD HEMMING !!

| COCSISTENT 3-FOLD HEM SEWING | With presser pat, 3-folded pocket-top is fed under the needle and sewn

consistently. Against bias or stretchy cloth, bottom-top synchronized feeding mechanism promises free from twisting completely. |

| AUTO POCKET-TOP HEMMING | Just enough to load a pocket-piece, 3-folding, sewing, heat pressingand

stacking are sequenced full automatically. Also, available to make plaids matching to the bias cloth without twisting. Simply pattern conversion of hemming width is available. |

| STABLE STACKING & PICKING | Pressed pocket piece is dropped down and stacked on the stacker tray completely. With feeder, pocket-pieces are fed to the stacker case after every 50 pcs. Stacker case keeps by 250 pcs. Picking out is allowed at any time with button pushing. |

| SIMPLE BUT ACCURATE HEM PATTERN GAUGE CONVERSION | With sliding plate, suspending presser, folding plates(left/right), folding

air, pocket piece is fed on and 3-folded accurately. This promises an accurate 3-fold hemming even if cloth is bias consistently. Hemming length : Max. 150 o. Hemming width : 8 ` 30 o. |

| AUTO HEAT PRESSER | Additionally auto heat presser is accessoried heat pressing automatically

after 3-folded hemming ends. This can omit iron pressing work by hand. Temperature and time are adjustable according to the cloth freely. |

| AUTO FABRIC LOADER | Auto fabric loader is flexible to the pocket shape and size freely. Pocket guide-bar location is removable according to the shapes and sizes. Pocket-piece loading is just enough to the face a pocket-top edge to the auto fabric loader face accurately. Max. loading height : 180 o. |

| FEEDING FLEXIBILITY ACCORDING TO POCKET-SIZE & HEMMING WIDTH | Adhesive rolled tape clamper location is adjustable according to pocket

size from 70 ` 150 o freely. Hemming width is adjustable 8 ` 30 o with feeding adjustment. Large variation such pocket size, hemming width is allowed. |

| FEEDER WITH ADHESIVE TAPE CLAMPER | Tape face is picked up by 0.2 o every. Adhesive rolled-tape clamping mechanism gives the highest reliability. Twin-rolled 10 o wide adhesive tape is equipped. Tape face is picked by 0.2 o every feeding and rolled up automatically. This promises a new pocket-piece is picked up newly all. |

| MANUAL FABRIC LOADER | Manual fabric loader is available when automatic fabric loader is not available. |

| MAINTENANCE | Simply sewing head tilting, operation checking step by step is applied

completely. High reliability for maintenance is applied completely. |

| THREAD BREAKAGE DETECTOR | When thread is broken, T.B.D. makes cycle sewing stop all at once. Available to avoid operation error in advnce. |

| DAILY OUTPUT | @1 cycle / 9 sec. @2,500pcs / 8H (20% allowance) |

|---|---|

| MAIN DEVICES | @@Auto fabric loader & feeder @@Auto heat presser @@Machine feed dog @@Bobbin counter @@Stacker & case @@Thread Breakage Detector (T.B.D.) @@Air gun @@Bobbin winder@<OPTION> |