|

■

NEW POCKET FACING SEAMER for L-Shape Folding & Seaming, for Straight Folding & Seaming U-3203-E/LW ■

■

NEW POCKET FACING SEAMER for Straight Folding & Seaming U-3203-E/W ■

|

Fully Automated Workflow of Attaching Pocket Facings with Space-Saving

Footprint

The U-3203-E is available in two models: the LW model and the W model.

Both models can be used to attach pocket facings to trouser side pockets

and hip pockets.

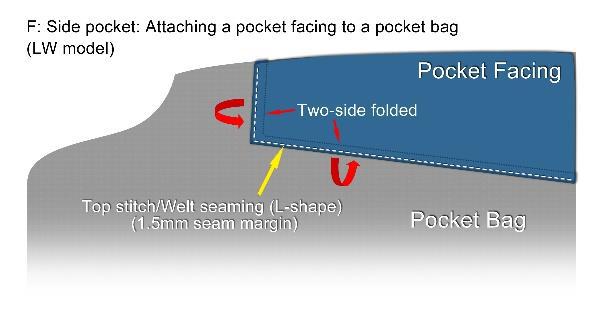

The LW model performs the following functions in the process of attaching the pocket facing of trouser side pockets:

1) automatically folds two sides (lateral and longitudinal) into an L-shape, and 2) automatically sews an L-shape with topstitching.

LW model can also cover attaching pocket facings on hip pockets (lateral straight folding and lateral straight topstitching).

The W model performs the following functions in the process of attaching the pocket facing of the trouser side and hip pockets:

1) automatically folds one side (lateral straight), and 2) automatically sews one side (lateral straight) with topstitching.

For both models, the operator only needs to set the material.

After setting, the machine automatically transports the material and performs the processes of "folding," "sewing," and "stacking."

The three-position design enables these three processes to proceed simultaneously,

resulting in high productivity.

| OVERLAPPING WORKFLOW DESIGN WITH SPACE-SAVING FOOTPRINT | At the garment factories, adding the pocket facing to a pocket bag consists

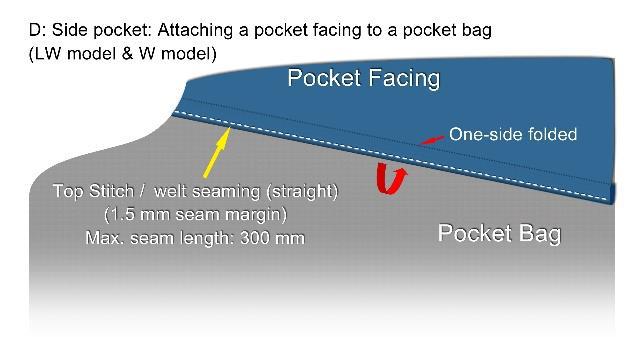

of two steps: a) Edge finish of pocket facing (serging, hemming, etc.)

and b) attaching the pocket facing with the pocket bag. The U-3203-E processes these steps in one step, resulting in a high-quality 1.5 mm welt seaming. It allows operator to insert care tag/washing label at the stage of setting material. Both the LW and W models can sew up to 300 mm in the lateral direction. In the LW model, the longitudinal sewing length can also be freely set within the range of a minimum of 10 mm to a maximum of 90 mm. By adopting a pulse motor, the optimum transport speed can be precisely set for each situation, such as high speed when transporting from the setting area to the sewing area and slow speed during the sewing process, to achieve high-quality seam results. |

| LCD TOUCHSCREEN PROMISES TACTILE OPERATION WHEN SWITCHING THE SEWING SPECIFICATIONS | Attaching the pocket facings to the pocket bags must be operated individually

for the left pockets and right pockets. U-3203-E allows operators to choose a workflow from the options: 1. Left pocket continuous, 2. Right pocket continuous, 3. Left and Right pocket alternately. These operations, including whether to insert a care tag, can be easily selected and switched on the LCD Touchscreen. When sewing L-shaped stitches (LW model), the depth stitch length can be easily set by inputting the numerical value on the touchscreen. As the fiber sensor automatically detects the start and end of the stitching accurately according to the length of the material, there is no need to input the width stitch length. |

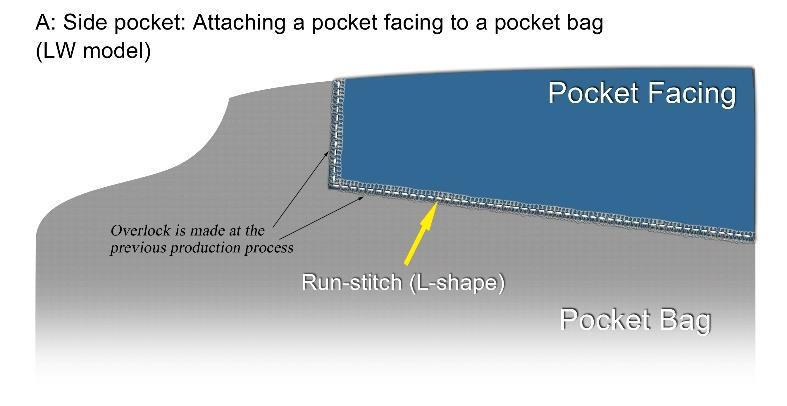

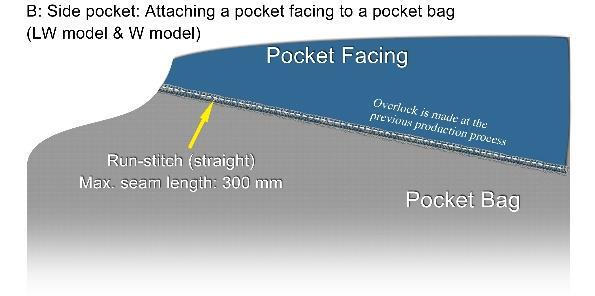

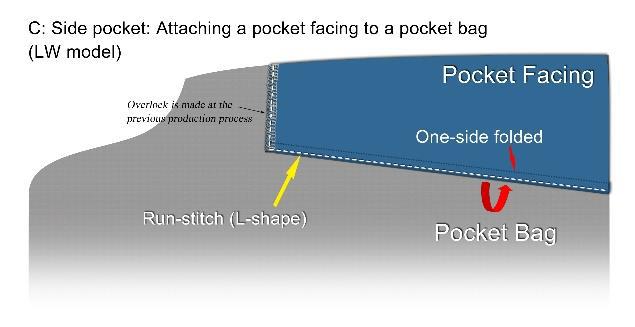

| FLEXIBLY COMBINE FOLDING AND SEWING ACCORDING TO SPECIFICATIONS | 1) Straight and L-shaped stitching without a fold  2) Straight and L-shaped stitching with one side folded    3) L-shaped stitching with two sides folded  |

| DIRECT DRIVE SEWING HEAD FOR HIGH EFFICIENCY AND EXCELLENT PRODUCTIVITY | The operator only needs to perform two actions in succession: 1) placing

the pocket bag in the correct position, and 2) placing the pocket facing. Accurate folding at the edge of the pocket-facing piece, switching the sewing direction at the correct position for L-shaped stitching (LW model) regardless of size differences, backstitching at the correct position at the edge of the fabric, and finally stacking neatly with the stacker. All of these tasks are handled automatically, so the operator does not require any special skills. Combined with the adoption of a direct drive sewing head, you can expect high-speed, highly efficient work. |

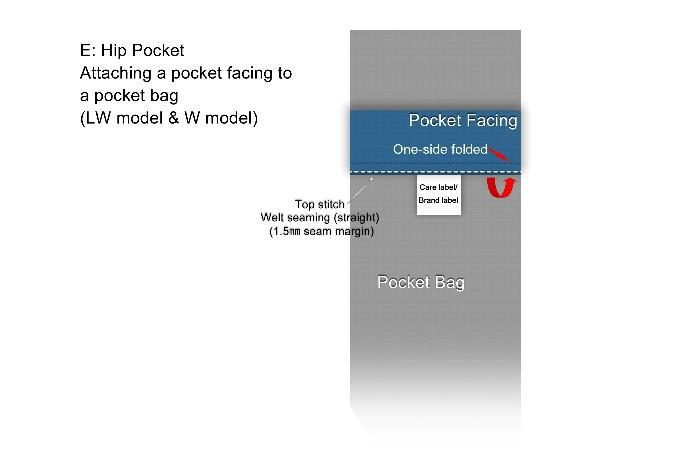

| POCKET FACING ON HIP POCKETS | For hip pockets, one side of the pocket-facing piece is automatically folded

and sewn. It is possible to either sew the pocket-facing piece with an overlock done during a separate production process or sew it all at once on U-3203-E without a separate overlock. When setting the pocket-facing piece, it is also possible to insert a care tag simultaneously with a simple operation. |

| A STACKER THAT ENSURES RELIABLE OPERATION | The stacker device on U-3203-E employs a clamping mechanism and a turn-over bar, enabling it to reliably and neatly stack the sewn material. |

| CAREFUL CONSIDERATION TO EASE OF MAINTENANCE | The U-3203-E has been designed with due consideration given to ease of

maintenance work after installation. For example, tilting the sewing head

and performing the setting and adjustment work that involves tilting the

sewing head can be done easily. U-3203-E is programmed with a sequence that automatically executes various operations in a predetermined order. It is, therefore, essential for operators and maintenance personnel to understand when and how each device operates during one cycle of the sequence. U-3203-E has a function that operates one step each time the pedal is pressed, making it easy to check the operation of each step. |

| T.B.D. (THREAD BREAKAGE DETECTOR) | In the unlikely event that the thread breaks, T.B.D. will automatically detect the break, immediately stop operation, and notify the operator. |

| DAILY OUTPUT | ★ LW Model : 11 sec. / cycle, 2,100 pcs. / 8 hours ( 20% allowance) ★ W Model : 10 sec. / cycle, 2,300 pcs. / 8 hours ( 20% allowance) |

|---|---|

| CONFIGURATION | ★ Setting the longitudinal sewing length on the LCD Touchscreen (LW model)

★ Stacker with Turn-over Bar and Clamper ★ L-shape/straight line select SW, run-stitching (without fold)/top-stitching (with fold) select SW (LW model) ★ Straight line stitching without fold (run-stitching)/ straight line stitching with fold (top-stitching) select SW (W model) ★ Vacuum Suction Functionality on the Table Surface ★ Cumulative Counter ★ T.B.D.(Thread Breakage Detector) ★ Air duster gun |