@@@ @@@ |

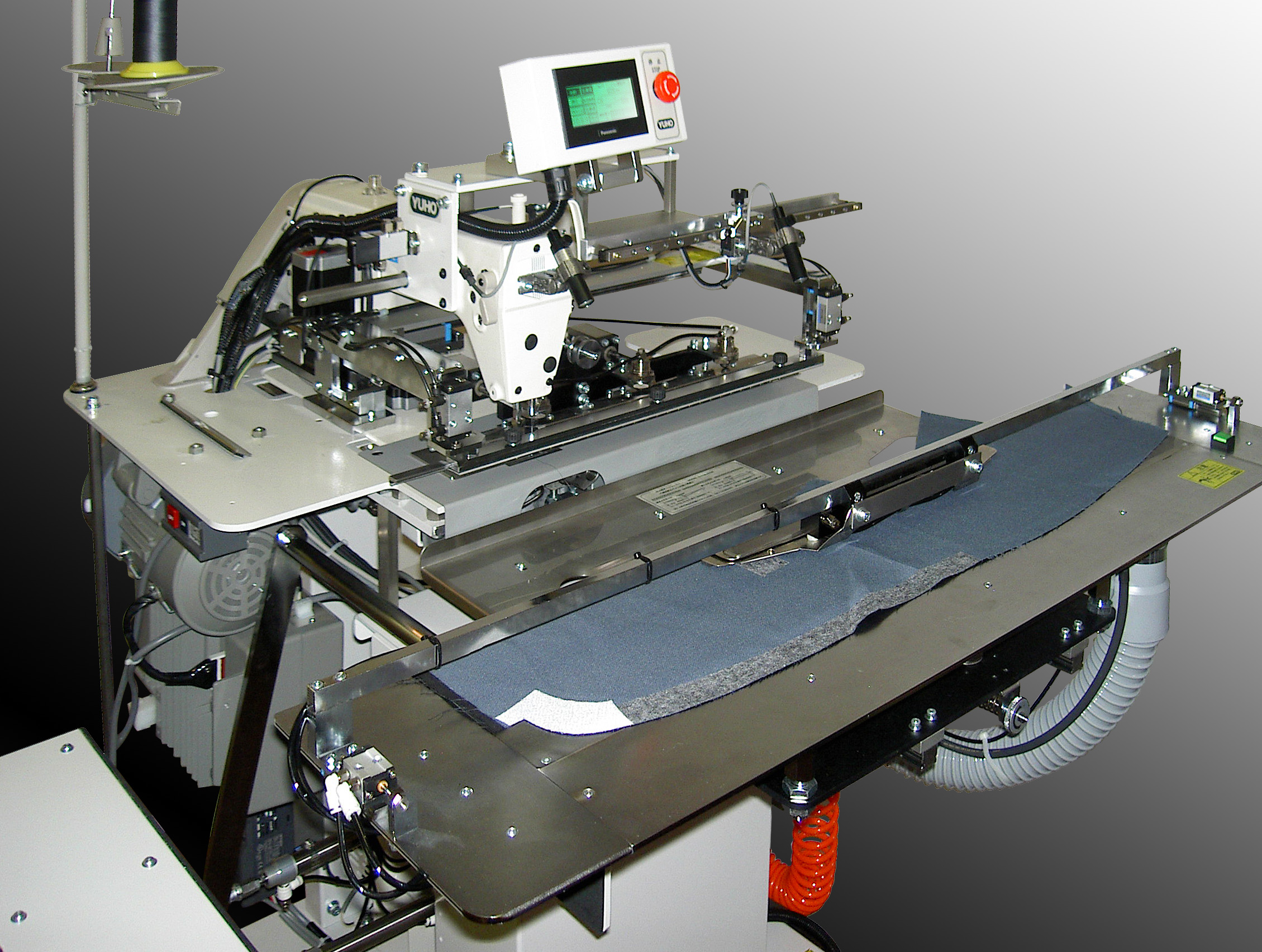

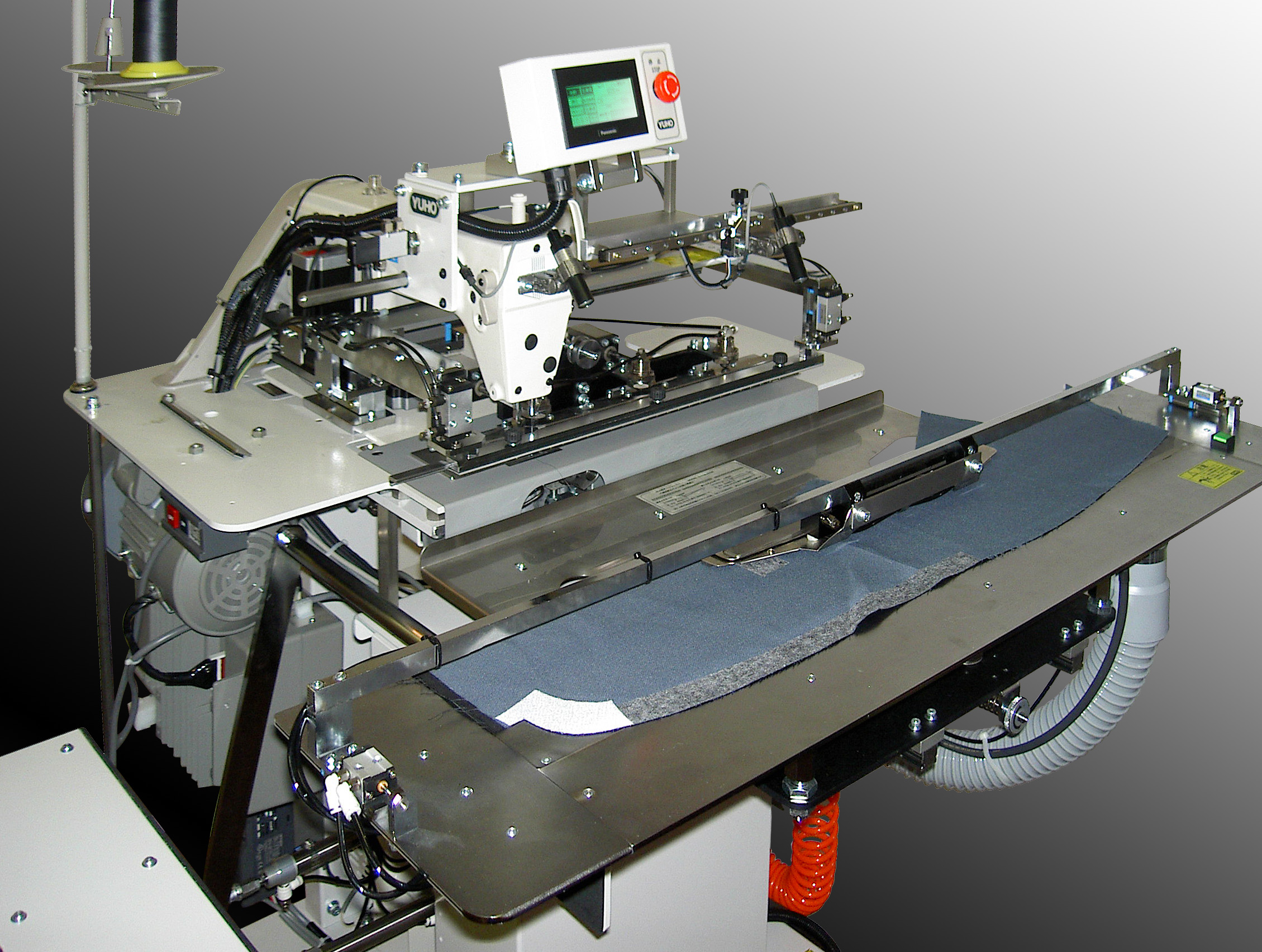

‘@NEW NC BREAST DART SEAMER U-3207-E/300@‘

@@@ @@@ |

NEWLY DESIGNED NEW NC BREAST DART SEAMER U-3207-E/300

WITH NUMERICAL PROGRAMMABLE BY LED DISPLAY PANEL IS

NOW APPLICABLE TO VARIOUS PATTERN SIZE SETTING FLEXIBLEY AS DESIGNED !!

NO USE OF GUIDE RAIL PATTERNS PRODUCING, NO NEED OF RAIL CONVERSION

AND PROMISES CONSISTENT BREAST DART SEWING,

AND FREE FROM PUCKERING, SEAM FAILING, ETC. !!

| PROGRAMMABLE TO EVERY BODY SIZES WITH LCD PANEL | With LCD display panel, every body-type and size are programmble and displayed

on the LCD display panel instantly. This is extremely advantageous for saving to make arail guide, because no need of rail conversion, dart size adjustment. This promises extraodinarly high-productivity and skilless and finest dart sewing. |

| FLEXIBILITY PROGRAMMING WITH LED DISPLAY PANEL | With LCD display panel, all of every body-size are programmble simply,

precisely and displayed. Top advantageous point is applicable to easy-order making no need conversion of guide rail, adjustment of sizes and patterns. This promises skilless, high-productivity. |

| MODIFIED TO LARGER SIZE DART SEWING MODES | Compared with former NC DART SEAMER, loading device dimensions are modified

to larger such as vacuumed loading platei1,000o ~ 250oj, advancing

plate i250oj. Dart tacking margin mofified upto 20o. After loading, with powerful vacuumed plate and keepers, fabric is held down and fed under the needle position without hand working. Dart sewing length, tack margin are promised accurately and stacked on automatically. The latest machine presser and dog-feed is applicable to thinner-fabrics without seam-failing. |

| HIGH FLEXIBILITIES TO VARIOUS DART SEWING PATTERNS | Normally, tape is attached on the fabric. When tape is attached on, attaching mode is different from left to right fabric loading. Dart pattrns, length tacks are varied to "DIA", "2-POINT" dart sewing. Also, cut-opened fabric with fused interlining, taping on the top of breast, etc. New NC DART SEAMER is applicable full-automatically for such dart patterns. |

| ORIGINALLY DESIGNED TAPE ATTACHING MECHANISM | Tape attaching mode is required differentially from left to right fabric,

tape for left fabric is to be loaded on the fabrics. When on the right, tape is over-turned under the plate automatically. This makes both fabrics same thickness. With left/right fabric selector switch, tape for left or right fabric alternates automatically or fixes on separately. Also, available to the cut-opened with interlining fabrics. LCD panel displays such mode is designed originally in the world by YUHO ! |

| FREE CHOISE OF SEWING START POSITIONS | Free choise of sewing start position is allowed according to sewing mode. 0 point or condensed starting point is allowed freely. Available to enter dart length, width, for 2-point, manipulate darts. Also, available to enter the starting position freely. |

| SIMPLY MECHANICAL ADJUSTMENT WITH LCD PROGRAMMING | With numerical control, fabric feeding speed conversion, back-tacking or

condensed stitching on the sewing start and end, sewing length,etc. are

free of choice. Dart sewing start 0 point is also allowed set on every 0.1o according to the thickness on the LCD display panel. |

| POWERFUL KEEPER HOLDING | Keeper of stainless unit leaf spring assures to aline the keeper-edge completely. Keeper holder on the gauge-edge supports to clamp the various fabrics such as heavier or soft, light fabrics completely. Keeper holder supports to make accurate dart tacking as designed. |

| STACKER WITH ARRANGER FOR FUSED INTERLINING FABRICS | Newly designed stacker with arranger allows to arrange thicker or fused

interlining fabrics and stacks on automatically. Also, with stacking timing adjustable according to longer or brief fabrics optimumly. With over-lapped working mode, high productivities and high consistent sewing are promised even if the beginners. |

| AUTO-TRIMMER FOR KNIFE TYPE DART SEAMER WITH KNIFE <OPTION> | MODEL U-3207-E/300 with knife type rtriims and collects the waste automatically. With knife ON/OFF switch, available to select knife ON or OFF mode. |

| FUSED INTERLINING FABRIC LOADING FOR MATCHING PLAIDS "TS" TYPE <OPTION> | Fabric holding lifter is located front of the loading plate. With LCD touch panel "TS" on, interlining fused fabric is opened up. After matching the plaids, push starting switch on. |

| THREAD BREAKAGE DETECTOR | When needle thread is broken, T.B.D. makes a sewing stop at once, avoid miss-operation. |

| BOBBIN WINDER <OPTION> | Bobbin thread can be wind at any time with switch on. |

@

| DAILY OUTPUT | @@BREAST DART 2,000 darts per 8H ( 20% allowance) |

|---|---|

| MAIN DEVICES | @@LCD display panel @@Fabric & tape presser @@Fabric loading lifter @@XY feeding NC controller @@Sewing START/END back-stitch or condensed stitching @@Machine dog-feed, machine presser lifter @@Large vacuume plate @@Marking light with transformer @@Stacker with arranger @@Stacker timing selector switch @@Knife ON/OFF switch @@Auto trimmer @@Air gun @@Thread Breakage Detector ( T.B.D ) @@Auto tape alternator ( Option ) |