|

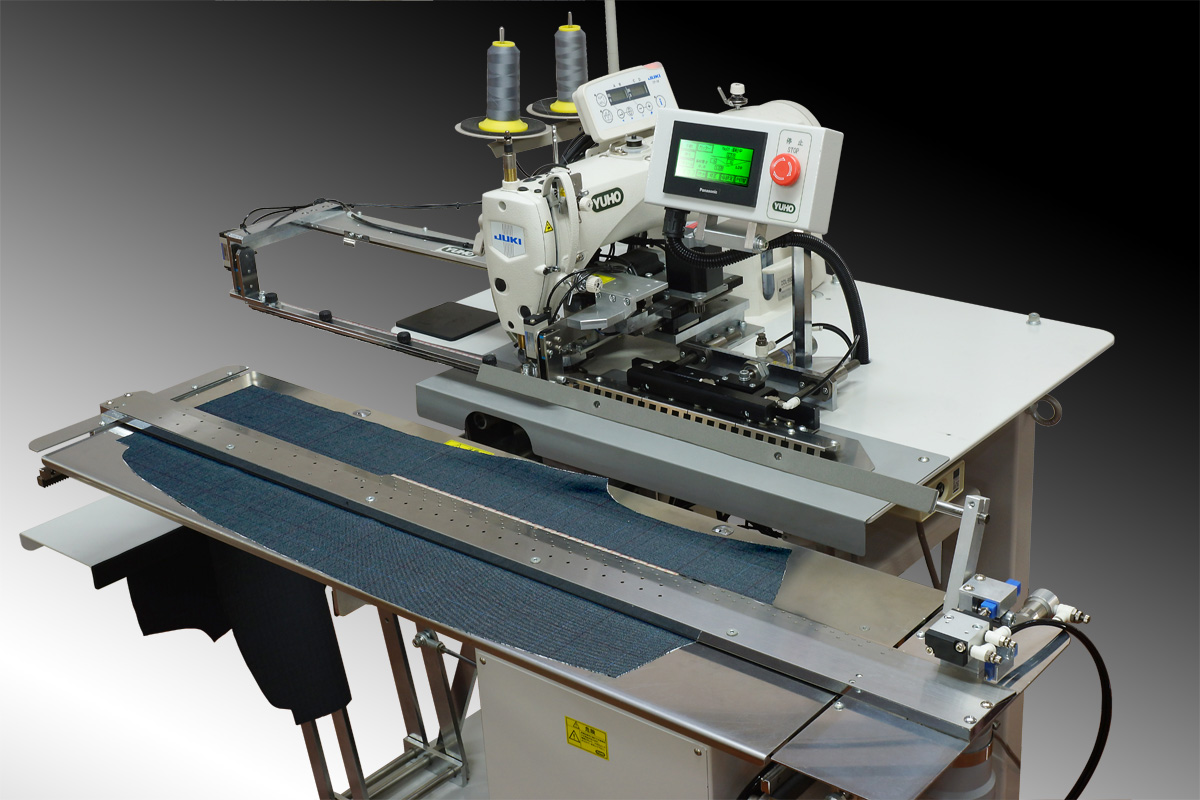

■ NC BREAST DART SEAMER Surface-side Loading System with built-in Disc Knife U-3301-E/350 ■

|

Cutting-Edge Breast Dart Seamer that

employs the Surface-Side Loading System and

Built-In Disc Knife

At the breast darts sewing process of men’s jackets, thanks to its surface-side

loading system,

U-3301 allows operators to make matching plaids even with the fabrics of

which plaid is not visible

from the reverse side due to the fusible interfacing covering opposite side of the material entirely.

Besides the super precision darts sewing, using its built-in disc knife, U-3301 lets the darts cut open

simultaneously till the position just 1 mm to the “zero” point.

It drastically simplifies the seam opening process of darts.

Needless to say, the acclaimed NC control system allows operators to sew darts of various shapes

and sizes, without producing dedicated gauges.

| STATE-OF-THE-ART NC DART SEAMER | Different from the conventional dart sewing machines which require the dedicated gauges/ guide rails etc., U-3301’s onboard computer calculates angles and shapes of various darts just by the input of length and depth. Especially for the breast darts, instead of the straight seam lines of darts on the conventional darts sewing machine, U-3301 can freely create convex curves and concave curves as you like. U-3301’s operating system incorporates YUHO’s unique technology which bends the seamline at the end of darts (and the beginning, as well), realizing the beautiful tip of dart without causing dimples. |

| PLAID MATCHING AND ADDING PATCH CAPABILITIES | U-3301’s surface-side loading system is the perfect solution for the demands

of plaid matching on the materials with fusible interlining covering the

reverse side of fabric entirely. Regardless of the stripe or grid pattern, U-3301 allows operators to check and align the plaid precisely visually. Once the operator sets material along the ruler on the loading plate, U-3301 flips and folds the material automatically and accurately without generating misalignment. Besides, the upper keeper device securely supports the placement of patches. Simple operation and no need to attend the operator’s hands at the process of feeding material to the needle; these are the massive benefit of this machine. |

| WIDE VARIETY OF DART PATTERNS ON YOUR FINGERTIP | Accurate and sharp corner (tip) of a dart is realized thanks to the capability

of delicate adjustment (in 0.1 mm) of dart setting in order to optimize

sewing results, including a wide variety of materials with different thicknesses. U-3301 covers wide range of darts sizes for jackets with various body shapes. Operators can input the size and depth of dart patterns on the fly with an LCD touch screen. Up to 60 patterns can be stored on the machine and recalled instantly. Naturally, dart sizes are different one by one with made-to-order suits. U-3301 is an ideal solution for such production site because operators do not need to replace gauges or make hardware adjustments at all. U-3301 enormously contributes to de-skilling, improving productivity, and equalizing quality. In terms of the double-pointed darts with a convex curve or single-pointed (trapezoid) darts with a concave curve, curved lines are adjustable delicately and smoothly on the LCD touch screen. |

| DISC KNIFE CUTS AND OPENS DARTS | The fabrics with the attached interlining on the reverse side may cause

extra thickness of darts, and therefore such darts are often requested

to cut and create seam opening. U-3301’s built-in disc knife is the ideal solution to realize 1) darts sewing and 2) darts cutting simultaneously. U-3301 can cut darts till the position just 1mm to the “zero” point. Disc knife position can be precisely adjusted depending on the different thicknesses of respective materials or the required depth of seam opening. High-speed steel is adopted as the material of the disc knife to guarantee excellent durability. Maintenance operations such as detaching, polishing, and attaching disc knife are so simple. |

| HEIGHT ADJUSTABLE TABLE TOP | The height and horizontal level of the top of the fabric setting table are adjustable instantly and precisely. This feature is advantageous to handle various materials with different thicknesses at the stage of setting materials between the loading plate and fabric setting table. |

| KEEPER SECURELY CATCHES NO MATTER WHETHER MATERIALS ARE THICK OR THIN | U-3301’s Keeper unit, made of a single piece of leaf spring, precisely holds a very sharp tip of darts on the variety of materials with different thicknesses. An operator can choose whether to activate or deactivate the onboard disc knife depending on the situation in order to get the best results of breast darts no matter thinner fabric without interlining or the fabrics covered with interlining. |

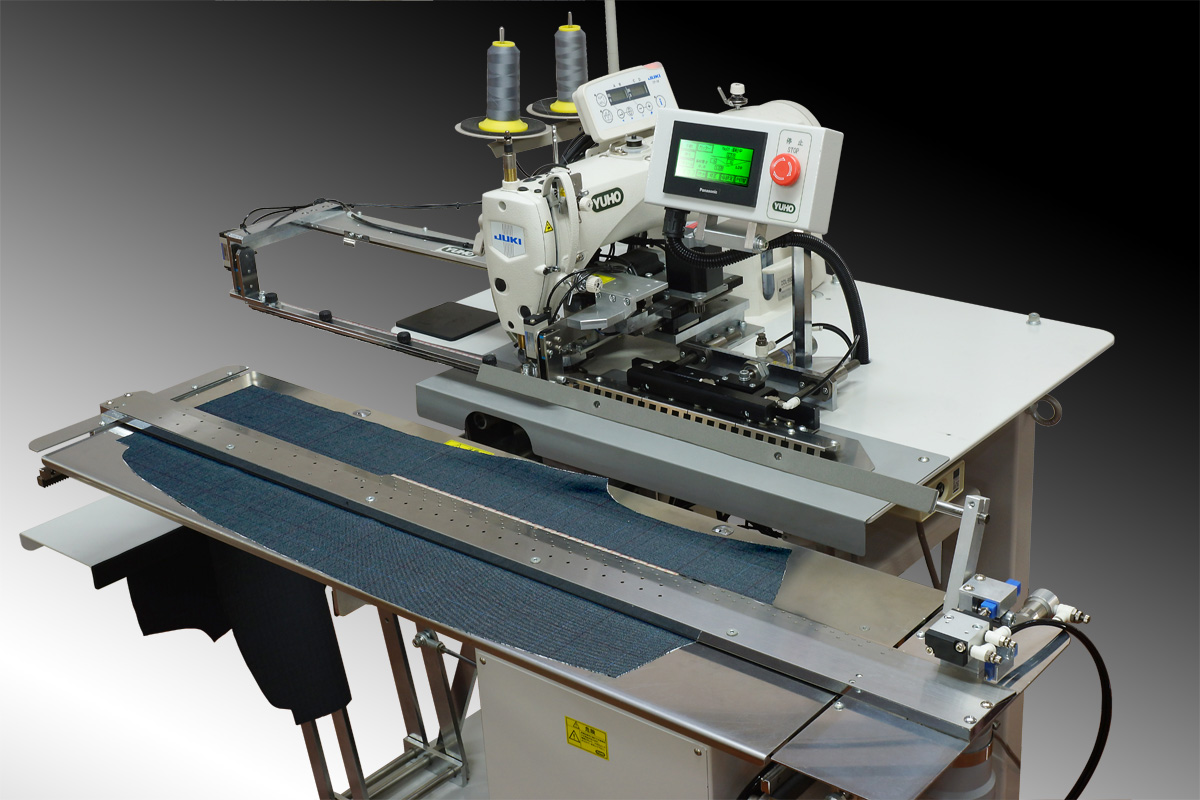

| DESIGNED FOR LARGER MATERIALS | Corresponding to the market trends of expanding material sizes, U-3301

equips the enlarged loading plate (with vacuum suction functionality) with

a 900 mm x 80 mm dimension and longer 250 mm forward/backward stroke. Consequently, the U-3301 can handle darts up to 350mm length and 12 mm depth. Thanks to the powerful vacuum suction functionality on the loading plate together with the upper keeper, materials are securely transported to the needle. Once operators put fabrics and set the position, U-3301 manages everything, and no need for operators to attend their hands. |

| STACKING MATERIALS SMOOTHLY | U-3301’s stacker section is highly optimized to handle front body panels

made of thicker fabrics and/or the fabrics covered with interlining. No matter longer items or shorter items, the stacker can pile up materials neatly, thanks to the adjustment of the “Stacker Position” parameter on the LCD touch screen. The automatic sewing process and the fabric loading process can be made simultaneously as overlapped workflow, resulting in a highly productive and efficient production environment. The onboard computer with large memory capacity allows U-3301 to offer not only accurate sewing results but also a wide range of operational and maintenance functionalities. For example, U-3301 detects thread breakage, stop operation immediately as soon as it happens, and minimize material loss. |

| HASSLE-FREE MAINTENANCE | U-3301 was designed to close attention to the ease of maintenance, inspection, and repair. For example, its keeper and keeper catcher are detachable instantly, and its sewing head can be tilted with simple operation. |

| DAILY OUTPUT | ★ BREAST DART 2,400 darts per 8H ( 20% allowance) |

|---|---|

| MAIN DEVICES | ★ LCD touch screen display ★ Large loading plate with vacuum suction and extra upper keeper ★ NC controlled XY drive ★ Disc knife ★ Auto scrap collector (with vacuum) ★ Disc knife front/back/left/forward position adjuster ★ Table height up/down adjustment functionality ★ Vacuum motor with Inverter ★ Stacker with turn-over bar ★ Keeper with guide ruler ★ Thread Breakage Detector (T.B.D.) ★ Wheels with brake |