|

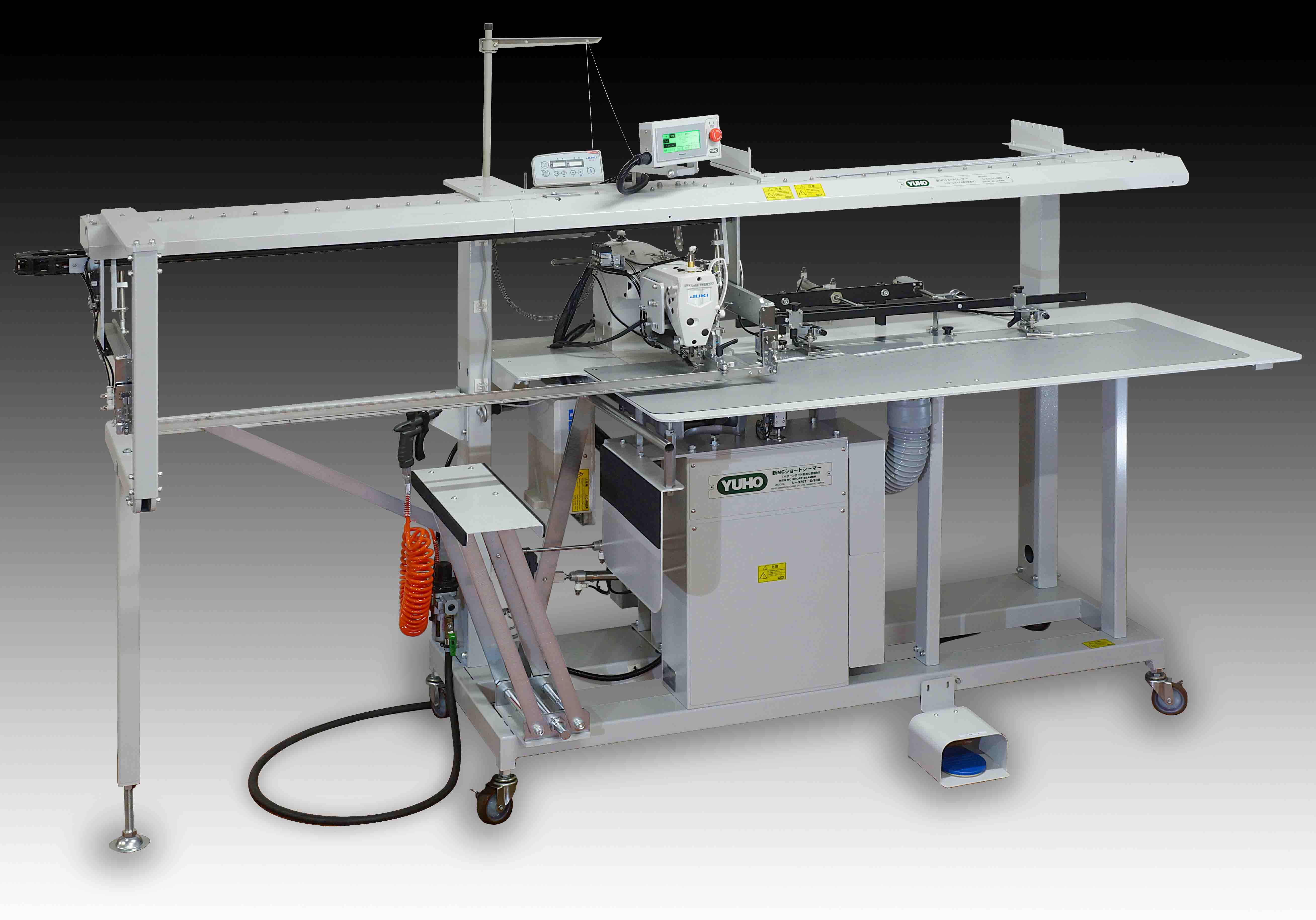

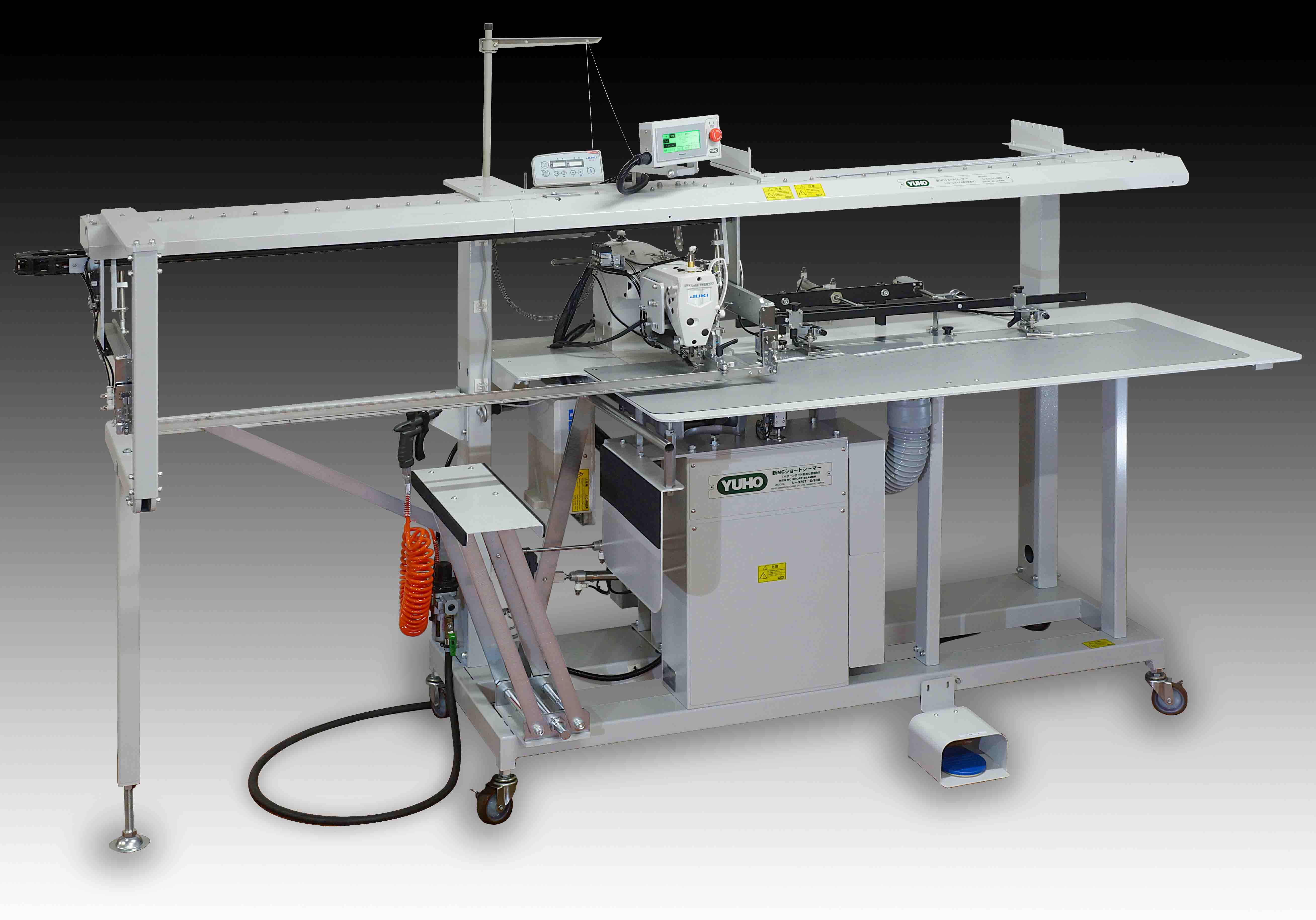

‘@ NEW NC SHORT SEAMER with PATTERN GUIDE MAKER@U-3707-E/900@‘

|

Unparalleled, Next Generation Short Seamer

YUHO has developed two product lines of Short Seamer machines:

the Pattern-Guide type and the Pattern-Guideless NC type.

YUHO has been offering both product lines to meet each customerfs requirements.

The brand-new U-3707-E/900 combines the stable seam results of the Pattern-Guide type with

the flexibility and low-running costs of NC type at higher level.

The U-3707-E/900 is truly a breakthrough in overcoming technical bottlenecks.

| NEWLY DEVELOPED PATTERN DATA INPUT TOOL | The brand-new U-3707-E/900 allows end-users to

manage the entire production process of extra pattern guides (Guide-Rail Pat

and Guide Ruler, made of acrylic panel) including pattern data input and

cutting by themselves with easy operations, with minimum cost and lead time. Pattern data, namely the shapes of (1) Guide-Rail Pat (= seam line) and (2) Guide Ruler (= outline of the cutwork) can be programed with easy data input method on the U-3707-E/900. Users can lay the pattern drawing on the acrylic panel, trace the lines using a special pointing device, marking the points (max. 14 points per line) following the LCD touch panel. Data editing/adjustment (point by point) procedure is also easy. Such custom-made Guide-Rail Pat securely holds the material while feeding, avoiding deviation or twist of fabric, and guarantees perfect seam lines. Since cutting and feeding actions are conducted by the computer-controlled XY stepping motor system, the U-3707-E/900 can handle complicated seam patterns which simple guide-rail feeding system cannot manage. |

| ACRYLIC CUTTER FOR MAKING GUIDE-RAIL PAT AND GUIDE RULER | With 1 ~ acrylic panel (max. 900 o ~ 170 o, 4 o thickness), users can make both guide-rail pat and guide ruler at once, using the acryl cutter functionality equipped with the U-3707-E/900. |

| KEEPER HOLD FABRICS LIKE YOUR HANDS | The procedure of loading fabrics is very simple. Just put the cutworks on the table, aligning the edges with the Guide Ruler. Supplied 2 sets of keepers (position adjustable: right and left, back and forth) are as useful as your hands. These keepers allow operators to grab and release the fabrics repeatedly. In addition, vacuum suction functionality is also equipped on the surface of the working table, assisting operators to set multilayered cutworks accurately. The operator can activate/deactivate vacuum suction at any time. These features are quite convenient especially for inserting quality labels or for ease stitching. |

| NO PUCKERING EVEN WITH VERY THIN GEORGETTE | YUHOfs unique gBobbin Thread Backtensionerh technology (patented in Japan) guarantees no puckering and perfect stitches on the back stitching or omni-directional stitching, regardless of material, thickness or elasticity. Its groundbreaking back-tensioning mechanism can always feed the most appropriate amount of bobbin thread. |

| INTUITIVE U/I TO LCD TOUCH PANEL | Sewing operations, sewing setup, pattern data creation, as well as periodical

maintenance and troubleshooting, can all be operated instantly with your

fingertip and LCD touch panel. The U-3707-E/900 has 7 different sewing styles. In case seam lines are not continuous, operators can measure the length of sewing skip using the Guide-Ruler, and input the length onto the touch panel. It also displays various information such as accumulate counter, remaining counter for bobbin thread etc. Red alert screen is displayed in case remaining bobbin thread reaches zero. |

| ENDLESS SEWING MODE AVAIABLE | Endless Sewing Mode allows sewing of longer items with straight seam lines

such as pants or skirts over 860 o in length. In Endless Sewing Mode, the machine head stops in the middle of sewing fabrics while the needle is kept stuck in the fabric. The guide-rail comes back to the loading area and the operator is allowed to set the remaining part with the Guide-Rail Pat. The machine continues sewing till the fiber sensor detects the end of fabric. Endless Sewing Mode enables the long seam lines without breaks or gaps. |

| THREAD CLAMPER IS STANDBY FOR TROUBLE-FREE SEWING | In order to avoid troubles at the beginning of each seam line, the U-3707-E/900

pulls thread using the Thread Clamper. Right after cutting the thread by knife at the end of the previous seam line, the Thread Clamper catches the thread, and releases it as soon as the needle moves. Since this procedure automatically takes place repeatedly at every single seam line, you are completely free from stitching troubles. |

| STACKER ENABLES OVERLAPPING WORKFLOW | After the sewing process is completed, fabrics are automatically picked

up and piled up by the Stacker device. It enables overlapping workflow and improves working efficiency. |

| THREAD BREAKAGE DETECTOR | T.B.D. circuitry perfectly detects thread breakage and stops the machine immediately, in order to avoid loss of materials. |

| MAIN DEVICES | @@LCD touch panel @@XY stepping motor system @@Pattern data input tool @@Keeper (2 sets) @@200 W powerful vacuum with inverter @@Stacker @@Air duster gun @@Thread Breakage Detector (T.B.D) |

|---|