|

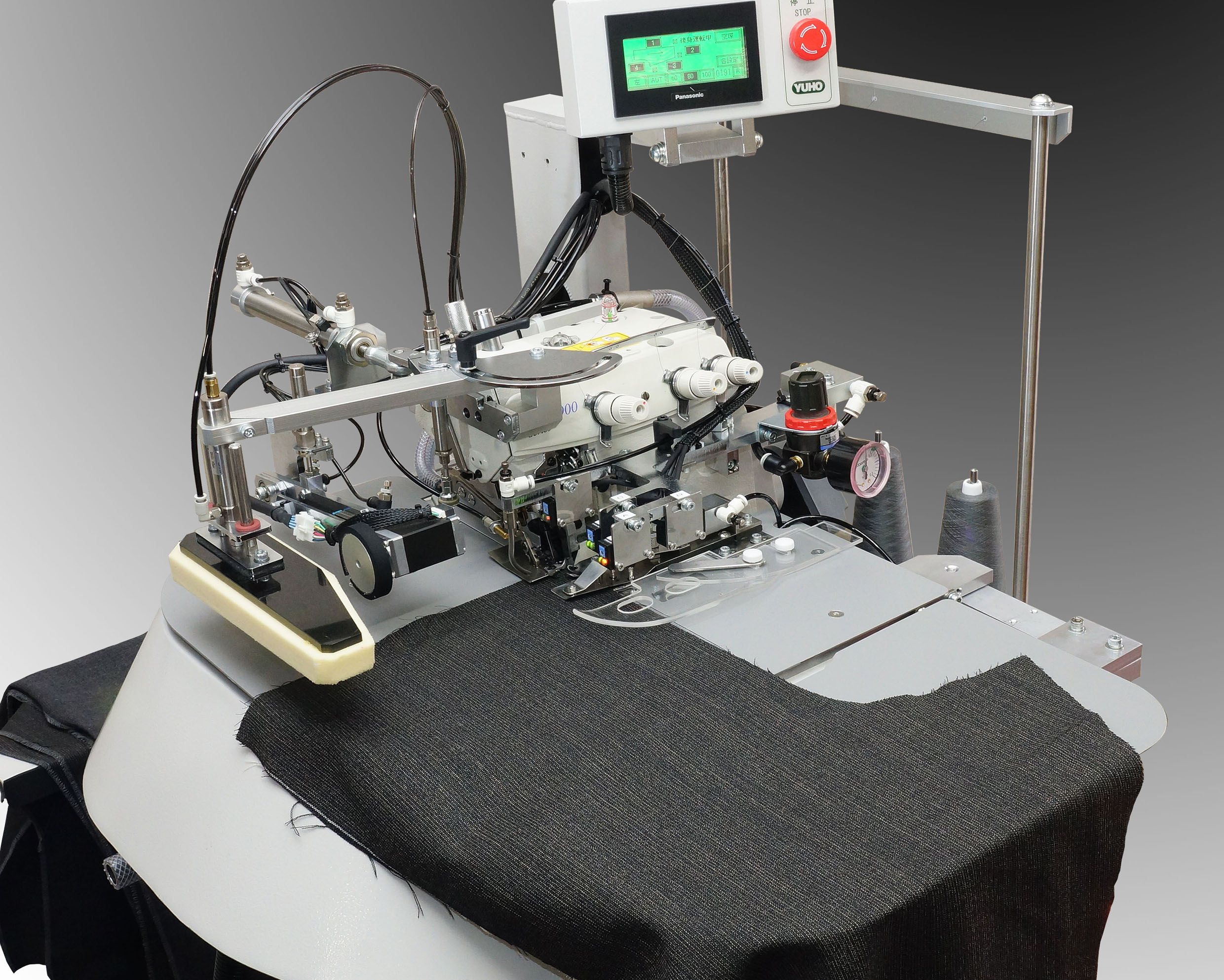

¡@NEW SERGER@U-3803-E@¡

|

Pursuit of Maximum Efficiency and

The Ultimate Easy-Operation

YUHOfs cutting edge serging machines realize gHands-Free 4-sides Full-Automatic Sergingh of pants (front body or back body),

allowing operators to choose either serging gcrotch firsth or serging gcrotch

last.h

In the case of serging pantsf back body with gcrotch firsth mode,

the former serging machines required operators to keep holding a corner of crotch at the beginning to prevent misfeeding.

Now the brand-new U-3803 allows operators to release the hands immediately,

and this feature contributes to improving cycle time and productivity,

reducing a loss (damaged items) of production, and emphasizing further

deskilling characteristics.

Parallel operation with two to four units by an operator is the ideal operation

method of U-3803.

| MAIN FEATURED POINTS | |

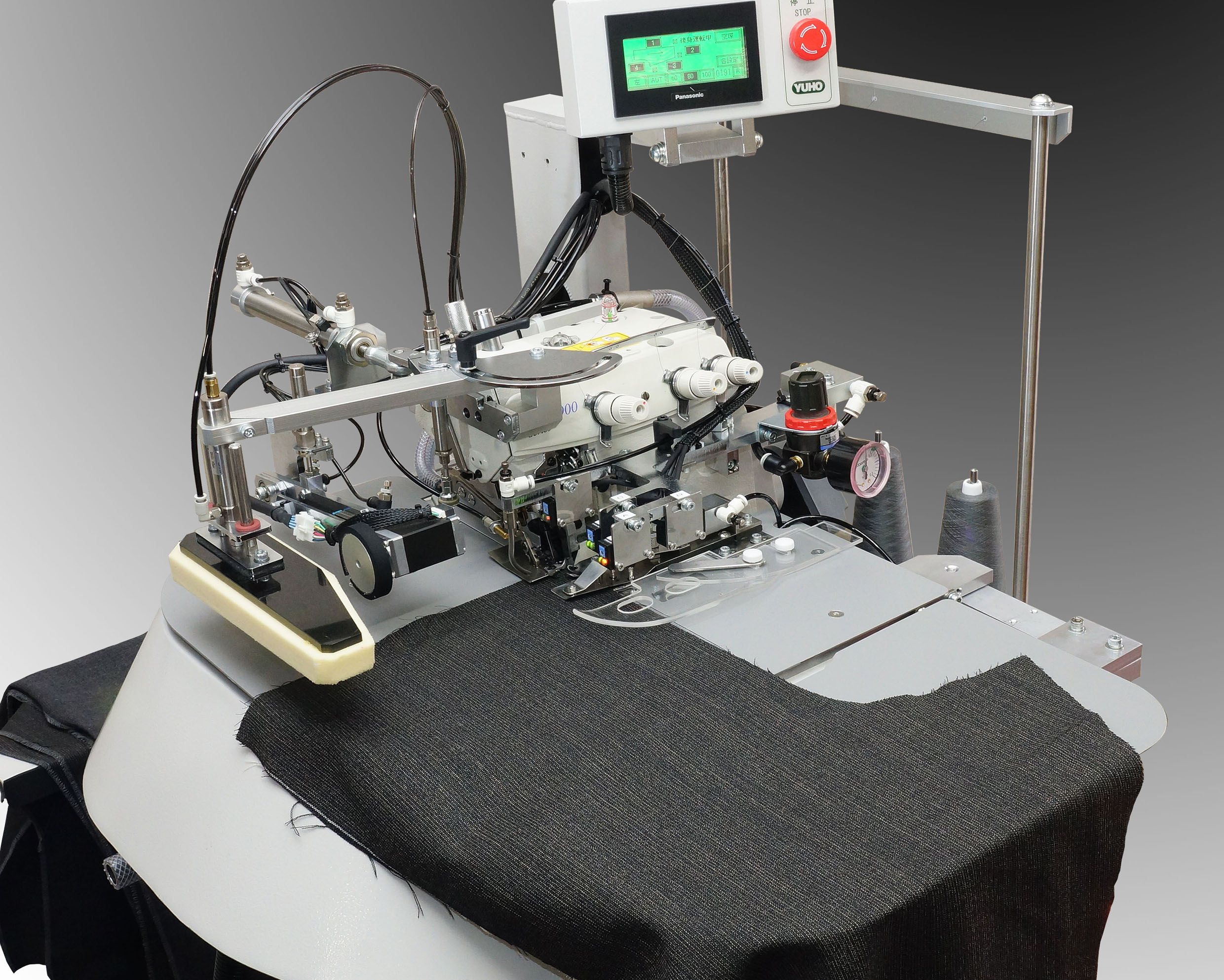

| NEW GENERATION SERGING MACHINE | Thanks to its intelligent software design in conjunction with the intuitive

touch panel operation system, U-3803 realizes Hands-Free 4-side full-automatic

serging (for trousers) with stunning sewing results, without cutting the

thread at each corner, saving the consumption of threads drastically. Coupled with its compact and space- saving footprint, U-3803 is ideal to use parallel operation with two to four units by a single operator. |

| STREAMLINED OPERATION REDUCING LOSSES | At the gHands-Free full-automatic sergingh with gCrotch First Mode,h former serging machine required operators to keep holding the corner of crotch at the beginning to support smoother feeding. Brand-new U-3803 allows operators just to insert the starting point under the presser foot and release hands immediately while minimizing misfeeding and losses. This improvement contributes shortening cycle time, reducing the mental stress of workers, especially for parallel operation with multiple (2 ~ 4) units. |

| INTUITIVE LCD TOUCH SCREEN | Configuring and switching various parametersc everything is at your fingertips Selecting the parts: front-bodies or back-bodies, left bodies or right bodies, 4-side sewing or just 1- or 2- or 3-side sewing, the setting of Feeder Rollerfs extension arm (mentioned below), etc. can be switched instantly on the LCD touch panel. |

| 4 x SENSORS DETECT CONTOURS | 4 sets of photoelectric sensors accurately detect the contour of trousersf

front and back body cutworks. Combined with digital servo motor (for machine head) as well as pulse-controlled motor (for Feeder Roller), U-3803 handles each cutwork on the table precisely and steadily on behalf of operatorsf hands. YUHOfs proprietary Edge Guide mechanism ensures accurate placement of fabric edges right under the needle. Thanks to the photoelectric sensor near the needle, U-3803 detects each corner accurately, and let the needle stops while stuck on the fabric. Then the machine turns the material and restarts sewing, realizing perfect 4-side serging without cutting the thread in the middle of an operation. |

| COMBINATION OF AUTO AND MANUAL | U-3803 allows operators to use their hands to support turning the materials,

especially in case of handling specific materials with characteristics

which may cause difficulties for U-3803 such as too thick / too thin /

too hard / too soft / too elastic, etc. Operators can designate the corner(s) where he/she wants to use their hands instead of using onboard turner. This function may minimize the losses due to the troubles such as unintended folding or jamming of fabrics. |

| CONVENIENCE IN SEMI|AUTO OPERATION | Flexibly designed U-3803 offers great convenience in case operators want to use their hands. Although the default position of onboard auto turner may be disturbing for hands, U-3803 can move it to the appropriate position, not interfering with the handfs operation. |

| FEEDER ROLLER WITH EXTENSION ARM | During the serging operation, depending on the shape and position of materials

from time to time, the onboard Feeder Roller changes its position thanks

to its extendable arm. Operators can instantly designate the timing when the arm should be extended, on the LCD Touch Screen. |

| FLEXIBLY DESIGNED STACKER | U-3803 is equipped with a unique stacker section specially designed for

the serging machine which handles fabrics much larger than its working

table. At the end of serging, just before a material is picked up by stacker, a Table Extender Bar jumps out in order to keep the material level. Stacker Turn-Over Bar also stretches its length in order to secure steady results of piling up larger materials.. |

| 2 x SERGING START MODES | Operators can choose either gSensor Start Modeh or gPedal Start Modeh. It allows beginner operators to choose gPedal Start Modeh for steadier operation until they get used to the machine, and later they can choose gSensor Start Modeh in order to minimize cycle time. Those two modes are also available at the moments when operator stops and restarts serging at the designated corner in order to use their hands for turning materials. |

| HASSLE-FREE MAINTENANCE | Drum-shaped table can slide to the left in order to offer easy maintenance including replacing needles, threading, cleaning, and discharging scraps of fabrics. |

| OUTPUT | |

| 1,300pcs@per 8h@(Trousers, 4-side serging) |

| MAIN DEVICES | |

| @@Feeder Roller with Extendable Arm @@4 x Photo Sensors (for detecting contour of fabrics) @@LCD Touch Screen @@Edge Guide for drawing fabric @@Fabric Turner (with retractable mechanism) @@Air Blow (for assisting fabrics feeding) @@Vacuum Suction (for chain-off thread or scrap of cloth) @@Stacker (with Extendable Turn-Over Bar & Table Extender Bar) @@Digital Control Servo Motor for Sewing Head @@Pulse Control Motor for Feeder Roller @@Cycle Counter @@Air Duster Gun |