|

■

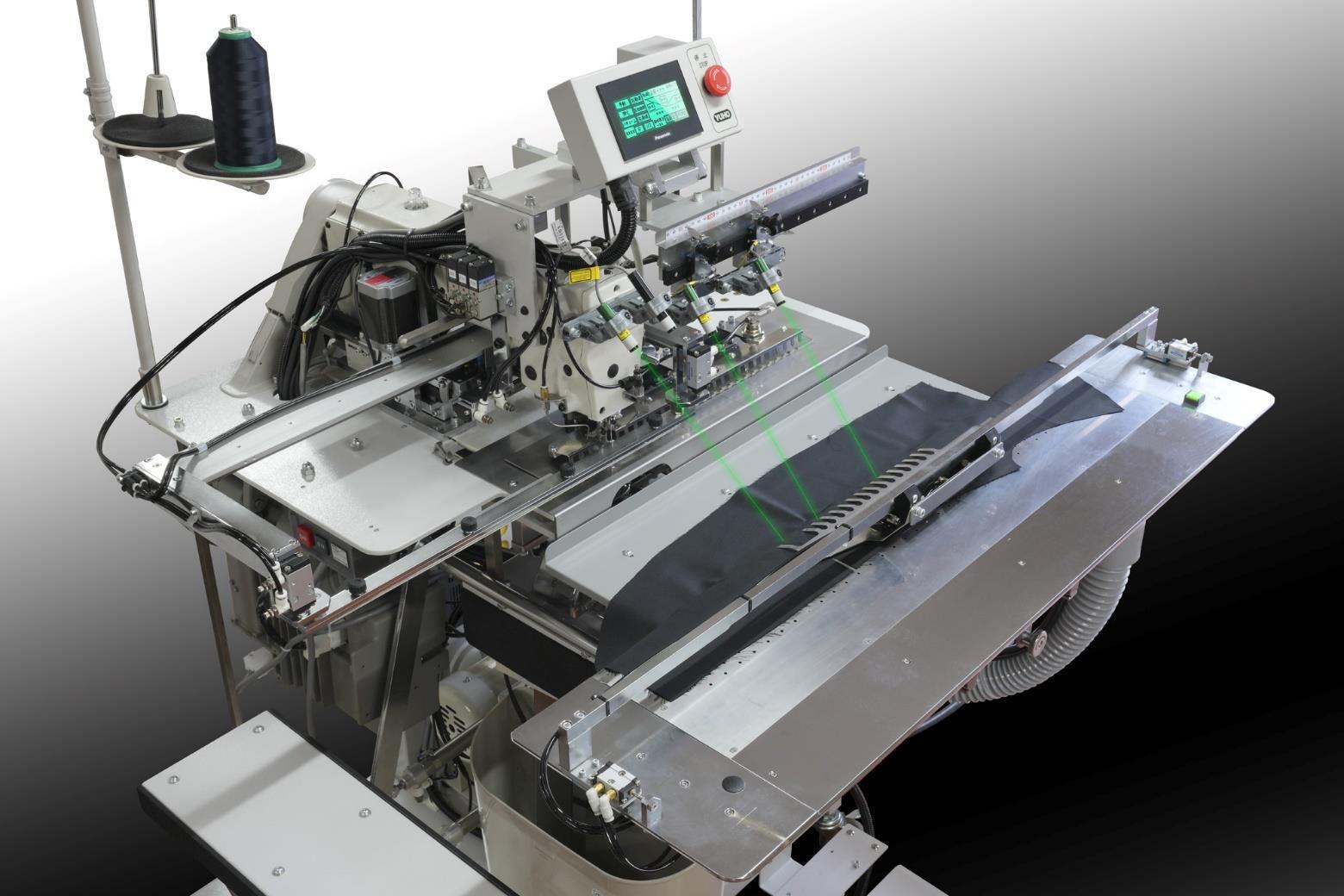

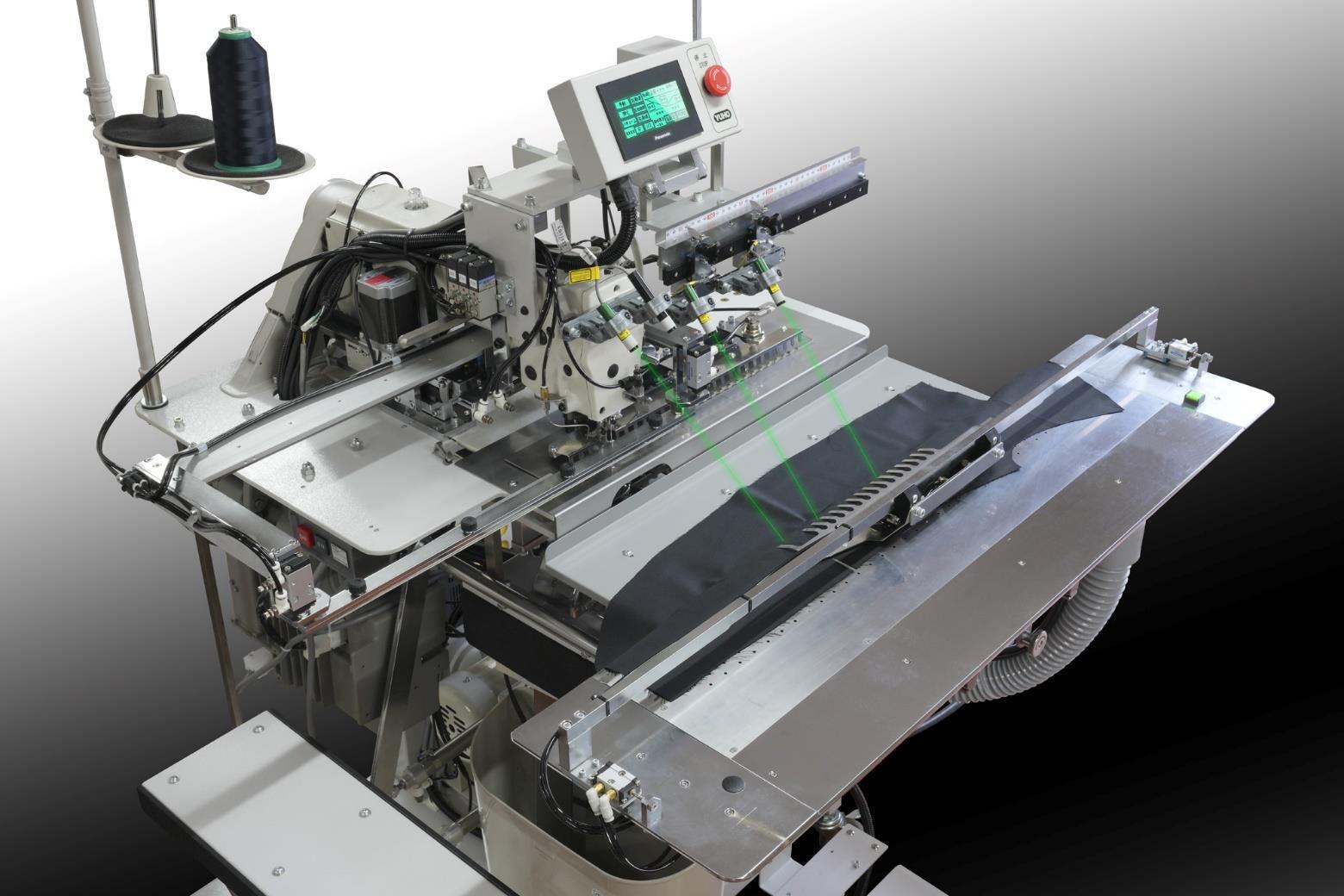

NC BREAST DART SEAMER With Auto Dart Length Measuring Tool U-3907-E/350 ■

■

NC BREAST DART SEAMER With Auto Dart Length Measuring Tool and Vertical Edge Trimmer U-3907-E/LM-350 ■

|

A unique NC breast dart seamer that is second to none in the world.

It eliminates the burdens of making custom gauges crucial

for dart sewing and detaching/attaching them,

and can accommodate all body shapes and sizes with a single touch.

The latest model is equipped with a cutting-edge Auto Dart Length Measuring Tool,

significantly contributing to semicustom-made suite production sites

where each jacket has different dart dimensions.

| UNPRECEDENTED AUTOMATIC SEWING MACHINE | This epoch-making automatic sewing machine can handle all types of dart sewing. Instead of sewing darts using custom-made gauges, the numerical control system calculates the angles to create the various sizes and shapes of darts. Thus, the time, effort, and cost required to produce custom gauges can be omitted entirely. The XY drive mechanism is incorporated with the pulse motors and realizes highly accurate dart stitching. |

| ALL DART SIZES ON YOUR FINGERTIP THANKS TO THE LCD TOUCHSCREEN | All dart patterns and sizes can be registered on the LCD touchscreen and recalled instantly. In production sites such as semi-custom-made suites, darts are sewn with different dimensions and shapes for each garment, and this can be done instantly with a single touch without gauge replacements and size adjustments. This automatic machine meets the needs for de-skilling, higher productivity, and higher quality. |

| WHAT YOU NEED IS TO ADJUST THE HORIZONTAL POSITIONS OF MARKING LIGHTS | When sewing breast darts, such as semi-order-made jackets where each one

has different dart dimensions, the operator only needs to move two marking

lights left or right so that the optical axis of the marking lights is

right on the marked positions (marked by eyelet or marking pen) of the

halfway point and endpoint on each material. The onboard Auto Dart Length Measuring Tool will complete inputting the dart length right at once. Note: The depth of the darts must be set separately. |

| EXPANDING COMPONENT SIZES AS PER THE TRENDS OF ENLARGING MATERIALS | In response to the trend of expanding material sizes, we have modified

the size of the material set plate, equipped with vacuum suction, to a

large plate of 250 x 1,000 mm and its forward/backward stroke from 200

mm to 250 mm. The dart sewing depth has been changed from 9 mm to a maximum of 20 mm, and the dart sewing length has been expanded from the previous 300 mm to cover a maximum of 350 mm. When setting the material, a powerful vacuum suctioned plate with only 4 mm thickness and a material holding device ensure that the material is reliably held and fed to the needle. Dart dimension settings are equipped with marking lights that can be moved according to the length, and a total of 3 lights, one fixed light on the left side and two movable lights are provided to set the dart length and position darts in the front panel accurately. The dart length/dart position setting can be operated easily and instantly. After setting the material, the operator does not need to touch it at all; dart sewing of accurate length and depth is automatically performed, and after being transported to the stacker section, it is automatically stacked. In addition, U-3907-E/350's low-tension presser foot and feed dog secure superior-quality sewing results without puckering or twisting, even on thin materials, making it compatible with new advanced materials. |

| CATER TO ALL SPECIFICATIONS FOR MEN'S CLOTHING BREAST DARTS | When sewing breast darts on men's clothing, the patch cloth is often attached

and sewn simultaneously. The position of the patch cloth is different for the left and right panels. There are also variations of dart shapes, such as diamond and trapezoid darts. Each dart's length and depth must vary. There are also a variety of specifications, such as those that are cut open using adhesive interlining and those that patch cloth is placed in the area of the tip of the darts. This product has achieved the difficult task of creating an automatic sewing machine that can cover all of these darts' specifications with a simple, easy-to-use mechanism without spoiling productivity. It is a unique, original sewing machine that cannot be seen anywhere else. |

| VERSATILE PATCH CLOTH ADDING FUNCTIONALITY | How to attach patch clothes to the breast darts differs for the left and

right front panels. Put the patch cloth above the left and right front panels. When it should be attached below the front panel, U-3907-E/350 automatically flips the material; consequently, the patch cloth comes below it. Continuous operation modes of attaching patch cloth either on the right or left panels, automatic alternating operation mode of left and right panels, etc. are displayed on the LCD touchscreen, and you can freely select and switch operation modes. You can attach the patch cloth at the tip of the cut and open breast darts. U-3907-E/350 is the one-and-only dart seamer that can sew breast darts with attaching patch cloth simultaneously with versatility. |

| INSTANT MECHANICAL SETTING AND ADJUSTMENT THANKS TO ELECTRONIC CONTROL | You can freely set various settings, such as changing the feed speed and

selecting the locking method at the start and end of dart sewing from the

back tack or condensed stitch, as well as that length. Depending on the thickness of the material, the dart tip can be set in minute increments of 0.1 mm with one touch on the LCD touchscreen, resulting in an accurate and sharp finished dart tip. |

| FREELY SELECT AND SWITCH THE SEWING START POSITION | Depending on the direction in which the material is set, it is possible to start sewing from either the Zero Point (tip of the dart) or the widening side of the dart. On the RUN screen, you can designate trapezoid, diamond dart, and starting position by directly inputting dimensions such as length and depth. |

| SECURELY HOLDS BOTH THIN AND THICK MATERIALS | The keeper blade is made of a single piece of leaf spring material, so

the tips of the keeper are in accurate alignment and hard to cause deviation. The keeper and the keeper base, integrated with the guide ruler, securely hold materials ranging from thin to thick. Even when sewing darts with extremely narrow-angled tips, you can sew breast darts precisely without a problem. The keeper base also prevents the tips of the keeper blade from contacting the table surface and causing scratches. |

| THE STACKER WITH TURN-OVER BAR ADAPTED FOR MATERIALS WITH INTERLINING | The stacker device with a new-type turn-over bar can neatly align and stack

even thick materials or the front panels with fully interlined. In addition, even for shorter items, particularly, the activation timing can be adjusted using the button on the LCD touchscreen to ensure stacking successfully. The automatic sewing-stacking process and setting of the following material can overlap, allowing even novice operators to perform dart sewing efficiently and precisely. |

| AUTO COLLECTION OF CLOTH CHIPS | With MODEL U-3907-E/LM-350, cut cloth chips are automatically collected. The LCD has an ON/OFF switch that allows you to activate/deactivate the knife. |

| HASSLE-FREE MAINTENANCE | U-3907-E/350 is designed carefully with maximum consideration for maintenance

and inspection. For example, the keeper/guide ruler unit can be easily attached and detached, and the sewing head can be tilted with few actions. |

| BOBBIN WINDER | A convenient tool that allows you to wind the bobbin thread freely at any time. |

| T.B.D. (THREAD BREAKAGE DETECTOR) | It reliably detects thread breakage and prevents work errors. It is also equipped with a bobbin thread remaining counter to notify the operator when it is time to replace the bobbin. |

| DETACHABLE SUPPORTIVE PRESSER | The guide rail installed in the U-3907-E/350 has a detachable supportive

presser mechanism that transforms its shape to accommodate the shape of

the sewing line as needed, ensuring higher sewing quality by pressing the

material area closer to the sewing line. The detachable supportive presser attachments that come standard with U-3907-E/350 consist of four elements: (1) Backslash, (2) Slash, (3) Horizontal Long, and (4) Horizontal Short. By attaching these individually or in combination, you can more stably sew the slanted lines of triangle, diamond, and trapezoid darts. Attaching/detaching can be quickly done by simply loosening the screws. By fine-tuning the position of the origin sensor dog in the front-to-back direction of the guide rail while checking the scale, more precise adjustments can be made according to the depth of the dart. |

| DAILY OUTPUT | ★ BREAST DART 980 darts per 8H ( 20% allowance) |

|---|---|

| CONFIGURATION | ★ Auto dart length measuring tool incl. 3 x marking lights ★ LCD touchscreen display ★ Elevator-type material setting support tray ★ NC controlled XY drive ★ Condensed stitch/back tack selector for sew start/sew end ★ large and thin vacuum loading plate ★ Feed dog, presser foot lift device ★ Blower motor with inverter ★ Patch-above/-below auto switching ★ Stacker with turn-over bar ★ Stacker start timing select SW ★ T.B.D.(Thread Breakage Detector) ★ Bobbin thread counter ★ Bobbin winder ★ Casters (front two wheels with brakes) ★ Air duster gun ★ Cloth trimming knife on/off SW (with vertical Edge Trimmer) ★ Auto cloth chips collector (with vertical Edge Trimmer) |