@@@ @@@ |

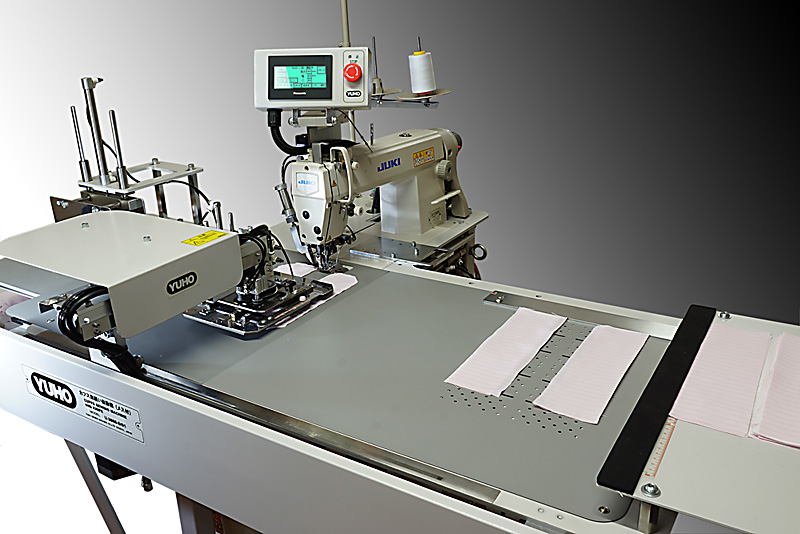

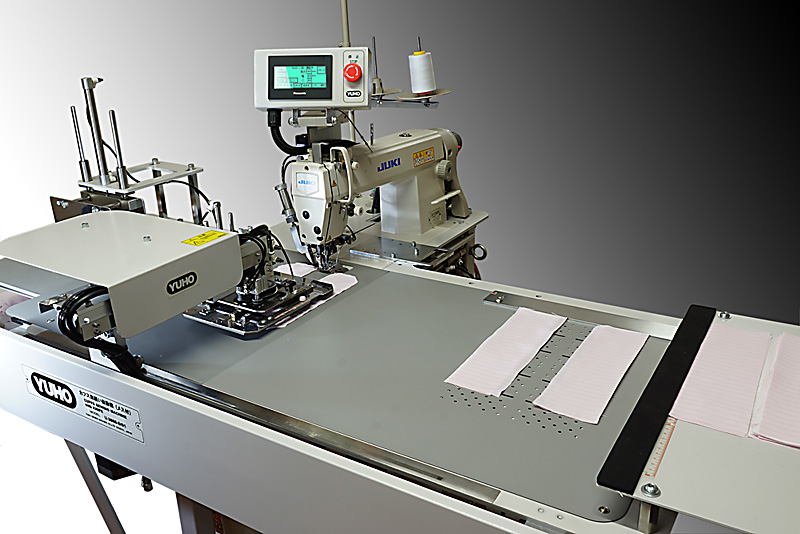

‘@CUFFS SEWING MACHINE WITH KNIFE U-4006-E/01@‘

@@@ @@@ |

| RUN STITCH SEWING AND CUTTING OF A PAIR OF L/R CUFFS SIMULTANEOUSLY | With the single-needle, lockstitch sewing head, this machine manages multiple

functions on a pair of cuffs in an automatic sequence including run stitching,

cutting fabrics, condensed stitches at both beginning and end of sewing,

thread trimming, and stacking. This machine was designed to have 3 independent working areas such as loading area, sewing area, and stacking area. Since the loading process and sewing\stacking process can be overlapped, operators just need to have easy loading/setting work (positioning fabric aligned to the guide ruler), and the remaining process can be done automatically and highly efficiently. |

| AUTO RUN MODE FOR HIGH EFFICIENCY | This machine takes approx. 16 sec. (it differs depending on the cuff shape

and sizes) for one sequence cycle. Operators can choose AUTO RUN mode in case the loading/setting work can be completed within 16 sec. At the AUTO RUN mode, the operator does not need to press start pedal every time as the machine repeats a sequencing cycle automatically, and it contributes to minimizing cycle time. By pressing the start pedal during the AUTO RUN mode operation, the operator can stop the machine at the end of the current sequence. The operator can re-start AUTO RUN mode by pressing the start pedal again. The Loading/Setting process of fabrics is so simple and easy, as the operator just needs to place each element of cuffs (left & right) aligning the guide ruler. The machine is designed allowing an operator to operate two units of U-3808 simultaneously for higher productivity. By turning a knob at the right edge of the table, 2 rows of guide ruler pins move left or right synchronously, and can adjust pin positions based on the size of cuffs. |

| COVERING 3 TYPES OF CUFFS INCL. SQUARE AND CUTAWAY | Thanks to the newly developed 3-spindle NC (Numerical Control) system, together with the PLC with larger memory capacity, this machine covers 3 types of cuffs (Round, Square, and Cutaway) |

| FLEXIBILITY FOR HIGH-MIX LOW VOLUME PRODUCTION | The machine covers cuffs length from 200 mm to 320 mm, thanks to the size-adjustable presser pat. This feature is highly advantageous for high-mix low volume production. Both ends of the presser pat can attach the magnet-detachable pat adaptors. Each pat adaptor corresponds to one cuff shape (out of three), allowing operators to replace the pat adaptor without any tool. The price of U-3808 includes 1 set of pat adaptors. |

| ONBOARD KNIFE FOR CUTTING FABRICS | Since this machine manages sewing and cutting fabrics simultaneously, users

just need to cut fabrics not precisely but roughly at the stage of pre-cutting,

and the machine does not require severe accuracy at the fabric loading

process by operators. Scraps of fabrics generated by this machine are suctioned by blower motor and discharged into a trash bin. Trash bin can be detached instantly. |

| MULTI-FUNCTIONAL STACKER | After the sewing process, a pair of cuffs are automatically transported

to the stacker section, pushed out to the lower table. Consequently, the pairs of cuffs are piled up in two rows. The bunches of cuffs are automatically ejected to the at the designated qfty. It is also possible to eject the bunch of cuffs at any time by pressing the EJECT button on the LCD touch screen. |

| INTUITIVE LCD TOUCH SCREEN OPERATION | In case of handles another cuff with different shape and sizes, the operator just needs to choose the pattern #, or choose the shapes (Square, Cutaway, Round), input length, depth, and corner size (in case of Round or Cutaway) on the LCD touch screen. Up to 40 cuff patterns can be stored and instantly recalled. |

| EASE OF MAINTENANCE | Press MANU on the LCD touch screen, and the machine shows each process of the pre-programmed sequence step by step, every time when the operator presses the start pedal. This is a convenient feature for the operators when they learn how to operate the machine or adjusting/optimizing the machine setting. The machine is designed to allow users to tilt and tilt back sewing head instantly for the ease of machine maintenance purposes. |

| OPTIONAL ACCESSORY | Magnet-detachable pat adaptors are custom-made one by one based on each customerfs required specifications, such as shape and size. The price of this machine includes 1 set of custom pat adaptor. |

| DAILY OUTPUT | @A Pair of L/R Cuffs/Sewing & Cutting : 1 cycle 16 sec. @(Cuff size: 70 mm x 250 mm x 20 R) @Approx. 3,200pcs. / 8H @(figure varies depends on size and shape) |

|---|---|

| MAIN DEVICES | @@Loading Table with Vacuum Suction @@Stacker with Eject Function @@LCD Touch Screen @@3-Spindle NC System @@Size-Adjustable Presser Pat @@Pat Adapter (Magnet Detachable Type) x 1 set @@Size-Adjustable Loading Guide Ruler @@Scrap Cloth Discharging Function @@Bobbin Counter @@Thread Breakage Detector (T.B.D.) @@Casters with Brakes @@Air Gun |