@ @ |

‘@

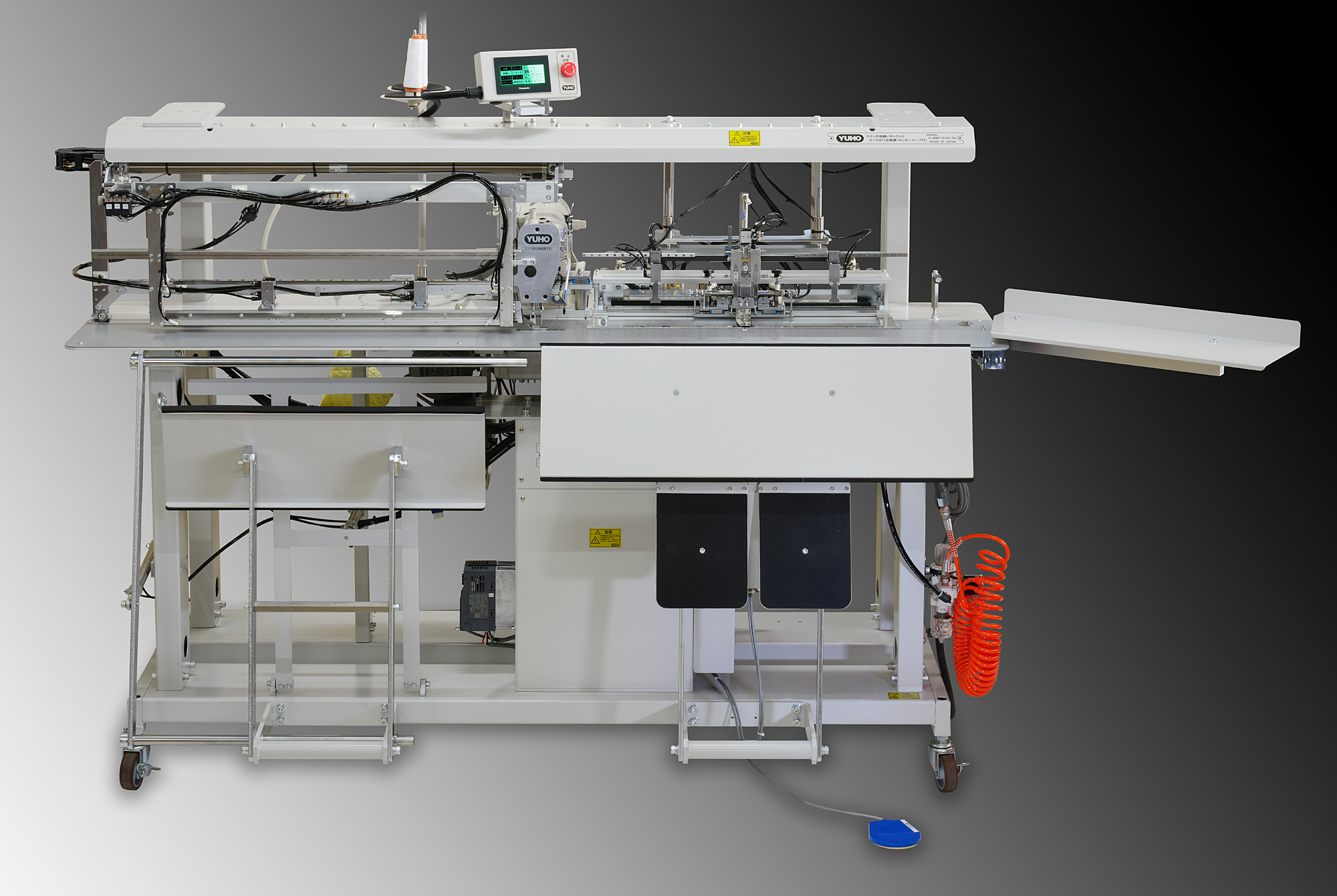

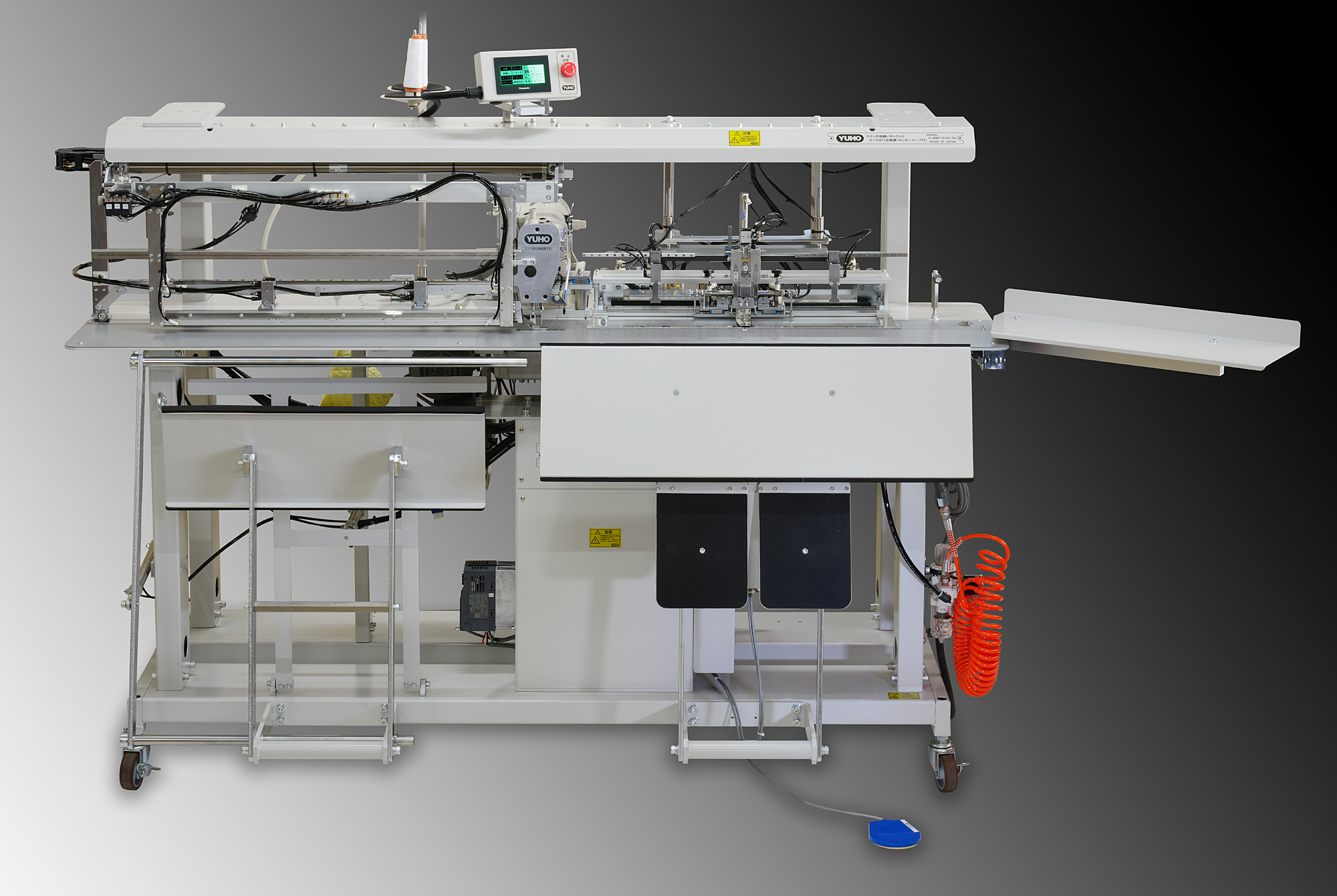

NEW TOP-STITCHING YOKE SEAMER with CENTER LOOP & PLEATING@U-4007-E/01 ‘

‘@

NEW TOP-STITCHING YOKE SEAMER with CENTER LOOP & PLEATING "SA"

Edition@U-4007-E/01-SA ‘@

@ @ |

Cutting-Edge, Fully Versatile Yoke Attaching

Machine Now Launches the SA Edition

This machine is undoubtedly amazing as it attaches the shirt yoke and back

panel and

simultaneously adds pleats and a center loop.

Everything is at your fingertip, whether run stitching or top stitching by welt seaming.

Flexibly designed onboard keeper devices (Left/Center/Right) realize sewing the curved yoke* and back panel.

In 2024, as a variant model, YUHO will launch a new gSAh Edition (U-4007-D/01-SA) that lets you quickly and

easily adjust the stitching margin by simply inputting values on the LCD

touchscreen without any troublesome manual work.

* Depending on various conditions, there may be curves that cannot be handled

by this machine.

| THE MOST VERSATILE YOKE-ATTACHING MACHINE EVER | U-4007-E/01 accepts a wide range of dress shirt yoke pieces in terms of

sewing length from Kidsf sizes to 640 mm* extralarge sizes. Besides, this fantastic machine covers 12 types of yokeattaching styles, allowing operators to select and switch variations instantly without using any tools. In addition to the coverage of functions for adding center/side pleats, the U-4007-E/01 incorporates the function of attaching a center loop as well as top stitch/welt seaming functionality just in a sequencing cycle. * Max. sewing length : 640 mm/Run-Stitch, 620 mm/Top Stitch |

| TOP STITCHING/WELT SEAMING WITH JUST ONE SEQUENCING CYCLE | The U-4007-E/01's unique mechanism delivers top stitching/welt seaming

on a yoke with just one sequencing cycle. The seam margin for welt seaming is adjustable instantly within 0.5 ` 2.0 mm. Thonboard yoke-flipping device flips over each upper yoke piece quickly, accurately, and reliably. The sub-guide rail holds yoke pieces together with the back panel, and the main guide rail, synced with the sub-guide rail, conveys them to the needle. This mechanism contributes to perfect welt seaming without puckering while reducing cycle time. |

| AUTO-ADJUSTMENT OF STITCH MARGIN (SA EDITION) |

With two additional stepper motors, the SA Edition (U-4007-E/01-SA) allows

operators to input the stitch margin on the LCD touchscreen, and the machine

will automatically change or adjust it. Adjusting the stitch margin for the left and right sides individually is also possible. |

| SWITCHING 12 STYLES JUST AT YOUR FINGER TIPS | From a run stitch without pleats to a top stitch with pleats and a center

loop, 12 yoke-attaching and variations can instantly selected on the LCD

touchscreen. Fine adjustments of various parameters, such as the conveying speed of guide rails, can be operated easily on the LCD touchscreen. |

| COMPATIBLE WITH CURVED BACK PANEL AND CURVED YOKE | Two sets of keeper units (Left & Right), a center keeper unit, and

vacuum suction functionality on the table surface are available for perfectly

loading materials. Besides, the needle-type keeper unit (specifically designed for top stitch/welt seaming) supports holding pleats (where the materials are layered) and prevents slippage of materials. Operators can change the positions of Left & Right keeper units instantly. If the operator touches one and changes its position, the other automatically moves symmetrically\there is no need to handle both. Due to the three-step action of those keeper units in conjunction with the center keeper and vacuum suction, the U-4007-E/01 can manage a curved yoke and a curved back panel. |

| PERFECT CONVERYING OF MATERIALS DUE TO SYNCED MOVEMENT OF MAIN AND SUB GUIDE RAILS | Due to the double chain stitch sewing head, the U-4007-E/01 guarantees high-quality seam lines with stretchability but without puckering. Furthermore, three-layered materials are held down securely and conveyed by two guide rails (main and sub) to keep the seaming area under the needle in perfect condition. This mechanism is the key to securing the highest quality of sewing. |

| ATTACHING CENTER LOOP | Attaching the center loop in the past required messy work. Now, the U-4007-E/01 allows operators to insert the center loop along the loop-attaching device, and then the machine sews the center loop together with yoke pieces and back panel all at once. The machine accepts a center loop with a minimum of 30 mm to a maximum length of 40 mm, and operators can easily optimize machine settings depending on size just by turning a knob. |

| FOLDING THE CENTER PLEAT/SIDE PLEATS | Two sets of onboard pleat folding device are for both center pleat (30

` 40 mm width) and side pleats (10 ` 20 mm width each). The mechanisms for folding devices (Left & Right) allow them to move symmetrically, so operators only need to touch one side and can set positions precisely symmetric without using any tools. The width of pleats can be adjusted instantly by turning knobs. |

| COMFORTABLE OPERATION WITH VACUUM SUCTION THANKS TO INVERTER | Thanks to the inverter circuitry, the onboard blower motor optimizes its rotating speed depending on the status of the vacuum suction functionality (ON or Stand-by) of the table surface and contributes to significantly reducing noise. In addition, it allows to fine-tune the output when operating the suction force at "Max" mode. The damper unit, equipped with the blower motor, has an instant detaching/attaching function, allowing users to open and close easily and quickly. This helps users to clean up dust or lint from time to time. |

| STACKER DEVICE ACCERERATES PRODUCTIVITY | Sewn materials are neatly stacked automatically by the onboard stacker

device. Needless to say, proper stacking materials contribute to improving efficiency in the following production processes, accelerating the overall productivity of final products. |

| INTUITIVE KNEE SWITCHES | Proper use of the keepers (Left/Right/Center) is crucial for setting up layered elements (lower yoke, back panel, upper yoke, and center loop). Using knee switches to operate keepers reduces operatorsf stress when setting those elements. Because one of the knee acts as Step Backward, it is convenient if the operator makes a mistake or wants to step back and redo the same procedure. |

| HORIZONTAL STRIPE MATCHING TOOL | Using the yoke piece with horizontally striped materials requires a line

of welt seaming stitches and a line of flipovers on the yoke piece, which

must be paralleled with the horizontal stripes. This function allows operators to match horizontal stripes, seam lines, and the line of flipover on the yoke piece. |

| OUTPUT | <<Run Stitch>> @ Without Pleats: 12 sec./cycle, 1,920 pcs./8 hours @ With Pleats: 17 sec./cycle, 1,280 pcs./8 hours @ With Center Loop: 20 sec./cycle, 1,150 pcs./8 hours <<Top Stitch/Welt Seaming>> @ With Center Loop: 22sec./cycle, 1,050 pcs./8 hours |

|---|---|

| CONFIGURATIONS | @ LCD touchscreen @ 12 Yoke attaching styles @ Two sets of Center/Side pleat folding devices @ Pleat folding device with symmetrical move mechanism @ L/R keepers with symmetrical move mechanism @ Center loop attaching device @ Needle-type keeper @ Synched move mechanism of Main/Sub guide rails @ Vacuum suction functionality on the table surface @ Blower motor with inverter @ Yoke clamping plate (for flipover the upper yoke piece) @ Two sets of stepper motor for adjusting stitch margin (U-4007-E/01-SA only) @ Knee switches (step forward/step backward) @ Foot switch (for horizontal stripe matching function) @ Stacker with turn-over Bar @ Air duster gun |