@ @ |

|

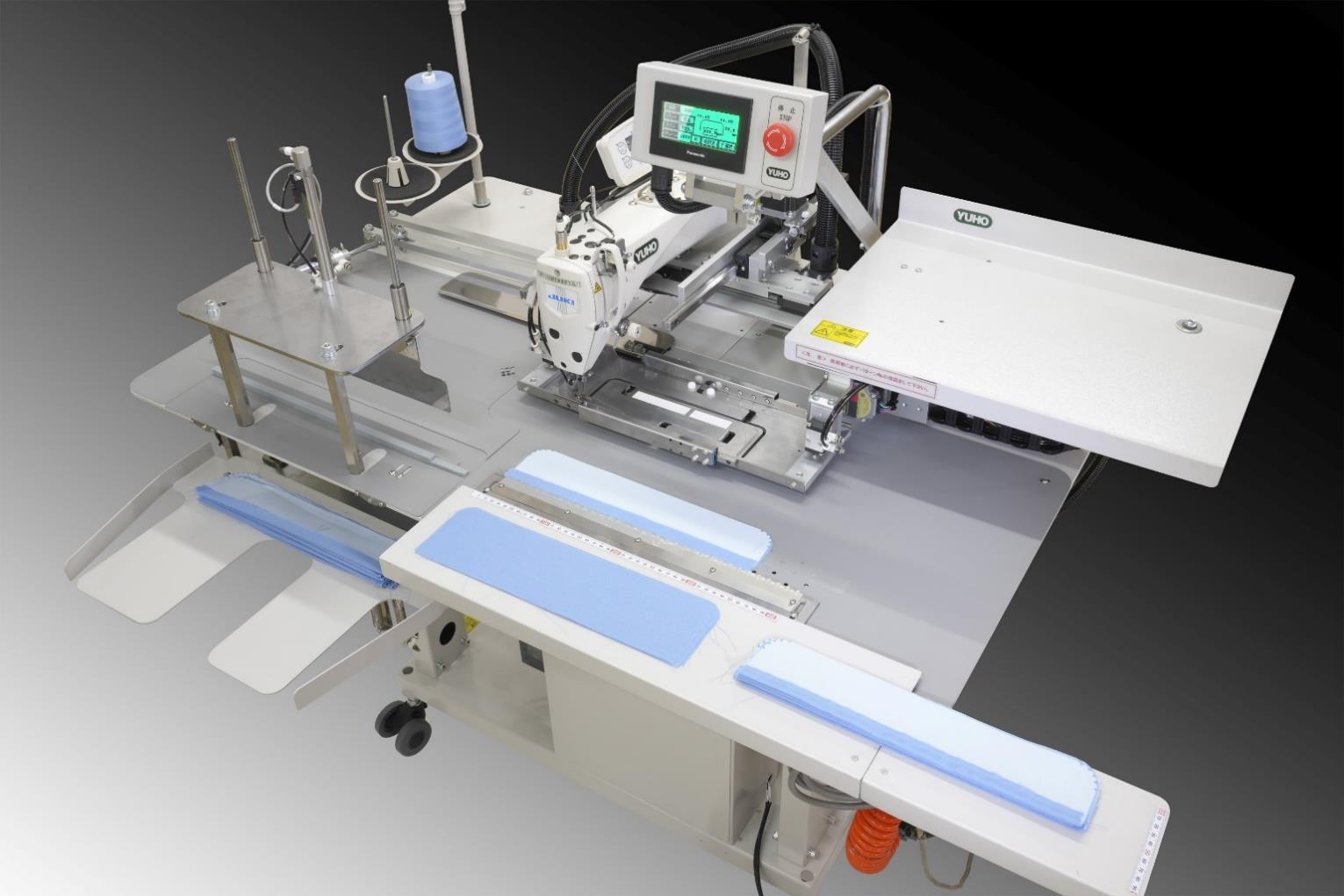

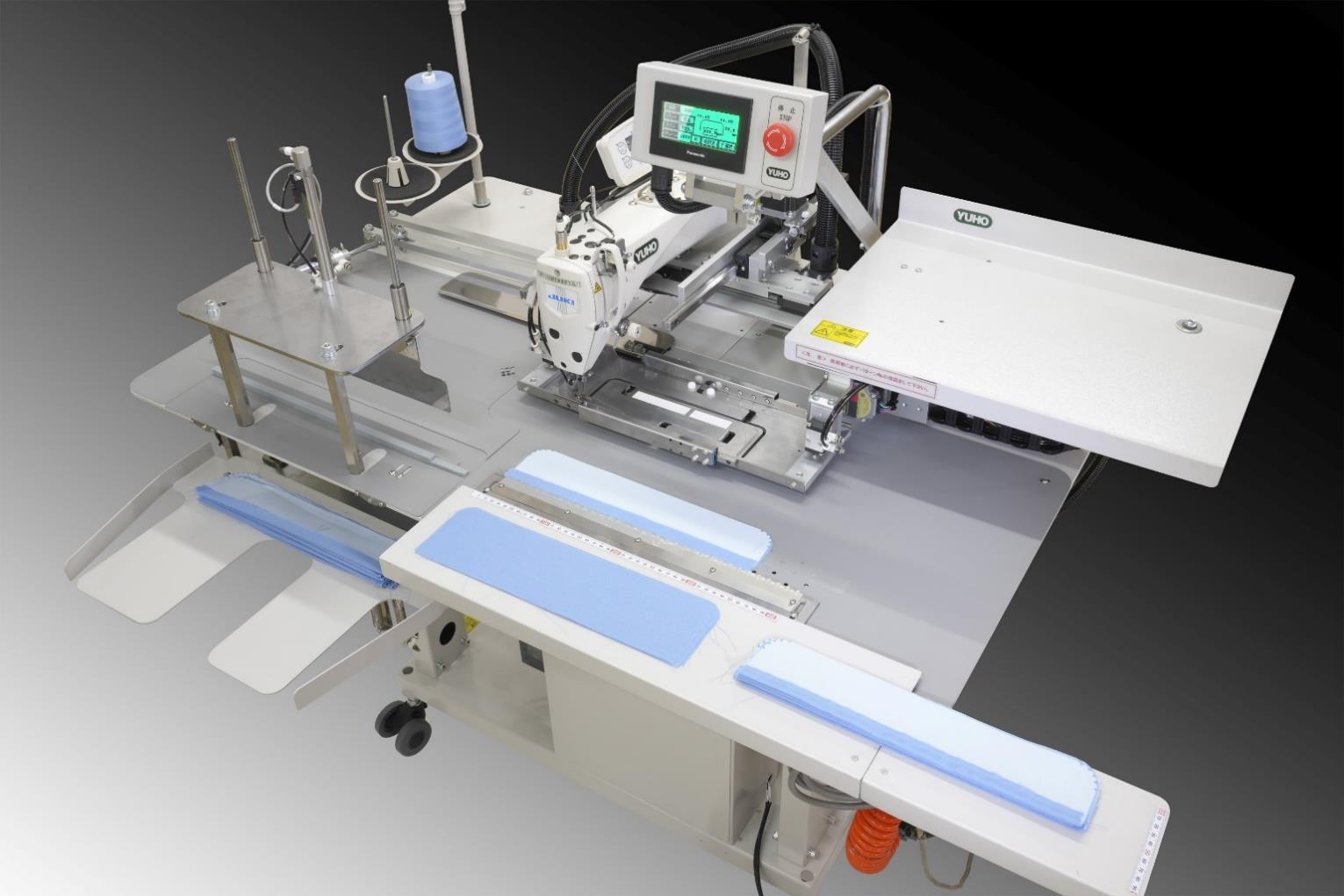

‘@@CUFF RUN-STITCH MACHINE@@@ U-4206-E@ ‘

‘@@CUFF RUN-STITCH MACHINE with auto engraving cutter@@@ U-4206-E/CP@ ‘

@ @ |

|

A state-of-the-art, 3-axis control machine

supporting 3 types of cuff shapes,

performing super-accurate auto-sewing/stacking,

with easy operation

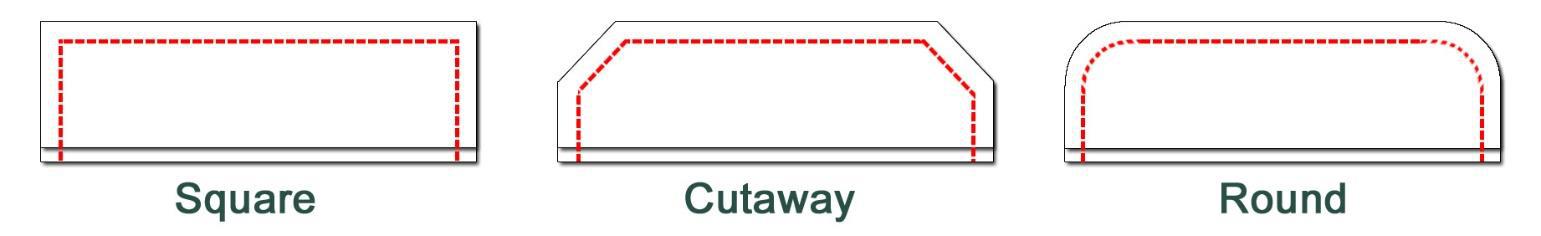

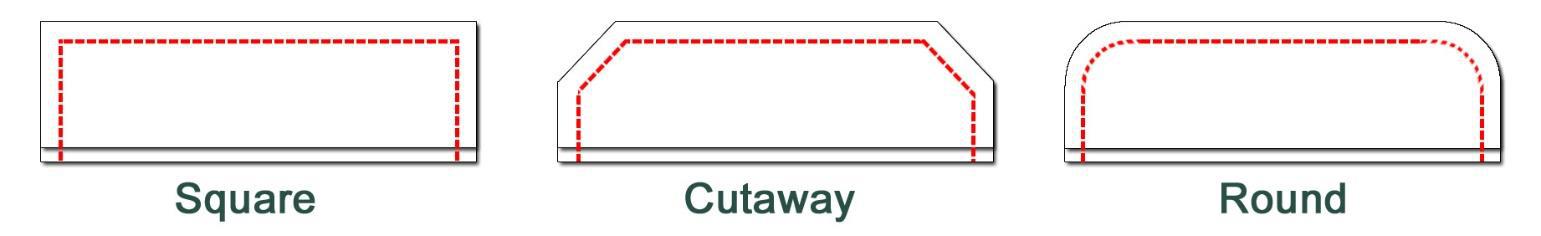

A single unit of U-4206-E can cover 1) round cuffs, 2) square cuffs, and

3) cutaway cuffs.

All you need is to place 2 x cuff pieces as a layer and fold the tip on a table equipped with powerful vacuum suction.

Then, the presser pat will transport the material under the needle,

and automatic sewing with precise size and shape is performed.

Immediately afterward, the drop-in-type stacker neatly aligns and stacks

the finished materials.

| IDEAL FOR HIGH-MIX, SMALL-LOT PRODUCTION | Enter the dimensions on the LCD touchscreen for cufflinks with various

sizes and the same shape. The same presser pat can manage various sizes instantly. For cufflinks with different shapes, you can instantly replace the presser pats by loosening the thumbscrews, and the sewing pattern data can be immediately switched on the LCD touchscreen. To satisfy the recent market demands of high-mix, small-lot production, the U-4206-E cuff sewing machine was developed with easy operation, multiple functions, and accommodation of a wide range of cuff shapes and sizes in mind. |

| COVERING THREE TYPES OF CUFF SHAPES | By newly adopting a 3-axis control system and large-capacity PLC, it is also compatible with cutaway cuffs and square cuffs, which were impossible with conventional machines, and this machine can handle three cuff shapes in total, including round cuffs. |

| NO NEED TO REPLACE GAUGE FOR SAME SHAPE/DIFFERENT WIDTH | If the cuff shape is the same but the cuff size is different, just input

the respective width and depth on the LCD touchscreen without changing

the pattern data (pattern memory #) and presser pats, and you will be able

to adjust the size for each size variation accurately. Suppose the shape is the same but different in width. In that case, U-4206-E automatically adjusts the interval of the presser pats, divided into left and right halves, according to the input dimensions, to accommodate various sizes. If the shape is the same but different in the size of depth, U-4206-E changes the sewing start/end positions using the same presser pats' vertical groove. Cuff size coverage is 230 to 400 mm (width) and 40 to 70 mm (depth). Up to 40 cuff sewing patterns can be stored in the U-4206-E. You can instantly recall and modify those patterns using the LCD touchscreen. |

| TABLE WITH VACUUM SUCTION MAKES ACCURATE LOADING EASY AND INSTANT | Place two pieces of material layered on the table with the vacuum suction

activated. Next, when folding a part of the overlaid piece, step on the pedal to increase the vacuum suction and the vacuum will keep the folded condition, so make sure to insert the mountain folded part under the claw of the guide ruler. Pull it toward operator and align the edge of the mountain fold precisely with the horizontal edge of the guide ruler, and also align it perfectly with the left edge of the guide ruler. When you press the pedal again, the carriage moves and the presser pat grabs the material with the folded part in and transports it under the needle. Automatic sewing is performed accurately according to the pre-programmed sewing lines, and the finished material is transported to the stacker drop-in section by the stacker arm, where it is neatly stacked downstairs on the table. The operator can begin loading the following material as soon as the carriage picks up the first material. Upon the material being sewn, the carriage handovers the material to the stacker's arm and immediately heads to pick up the following material, realizing an overlapping workflow within a single automatic sewing machine and achieving higher productivity. |

| HIGH PERFORMANCE STACKER | The drop-in type stacker device, designed especially for cuffs, automatically

drops materials from the table surface onto the elevator-type stacker table

downstairs, stacked neatly on the stacker table. When the q'ty of stacked materials reaches the preset number, U-4206-E will automatically discharge the bundles of materials that have been sewn. Additionally, you can take out the sewn bundle at any time by pressing the "EJECT" button on the RUN screen of the LCD. |

| DESIGNED FOR EASY MAINTENANCE | By turning on the "MANU" button on the LCD touchscreen, you can

perform a series of automatic actions of onboard devices step by step each

time you press the pedal, which is very convenient when checking the operating

order of each device and making adjustments. When performing maintenance on the sewing head, you can easily tilt the sewing head and return it to its original position. |

| OPTIONAL ACCESSORY | Custom gauges (optional) are available for each cuff shape. One custom

gauge set consists of two elements: left and Right.prsser pats. It can be quickly attached and detached without tools. All custom gauges are tailor-made based on the customer's desired specifications. (The photo shows the presser pats for the round cuffs) |

| CREATE PRESSER PAT AND SEWING PATTERN DATA IN-HOUSE, WITH SUPPORTING VARIOUS CUFF SHAPES | This machine allows users to create both cuff sewing pattern data and the presser pats, which are required to make each cuff design accurately and beautifully sew cuff runstitches without special tools or an external PC. We have made it possible to produce them in-house at the factory with zero delivery time. A 2mm-thick blank acrylic plate is the material for creating the presser pat, and the end mill built into the table surface of this machine applies the pattern data of the seam line input by the user to create a groove that follows the shape of the seam line. U-4206-E/CP automatically carves two pieces of layered acrylic plates at once. After cutting, it is simple to paste the sponge along the grooves and perform additional work. If the shape is the same, one acrylic presser pat can handle different sizes within 40 to 70 mm (depth) and 230 to 400 mm (width). |

| DAILY OUTPUT | @@Approx. 1,800pce. / 8H (with 20% allowance, the tact time varies depending on sizes and shapes of cuffs.) |

|---|---|

| CONFIGRATIONS | @@Vacuum Suction (Material Loading Area) @@Stacker System for Cuffs (with Eject Function) @@LCD Touchscreen @@40 x Pattern Memory @@Three-Axis Pulse Motor NC Control @@Presser Pat (horizontal length variable) @@Bobbin Thread Counter @@Thread Breakage Detector (T.B.D.) @@Build-in End Mill (U-4206-E/CP only) @@Casters with Brake @@Air Gun |