@ @ |

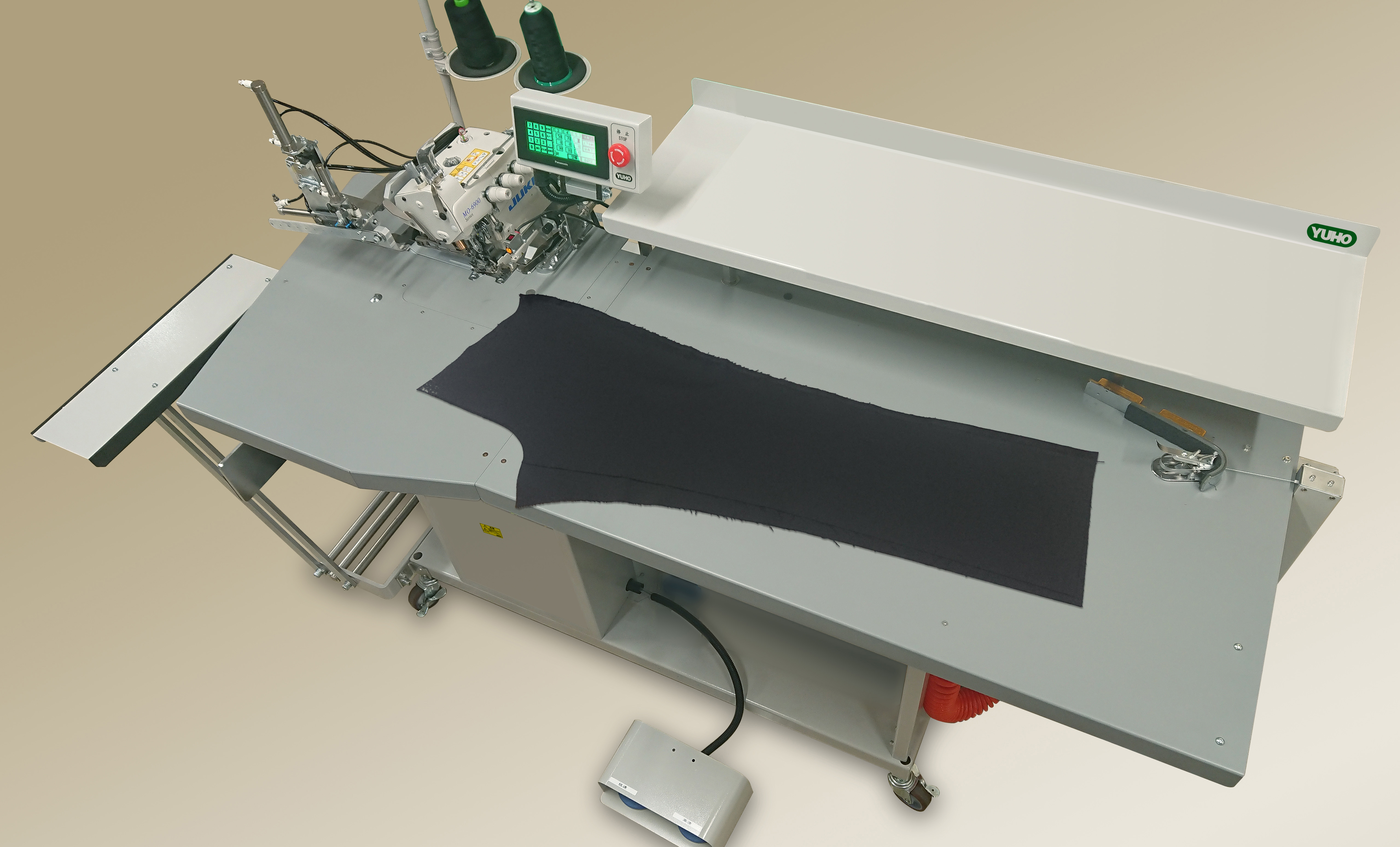

‘@ NEW SAFETY STITCH SEAMER with Top/Bottom-Individual Auto Shirring System@U-4309-E@‘

@ @ |

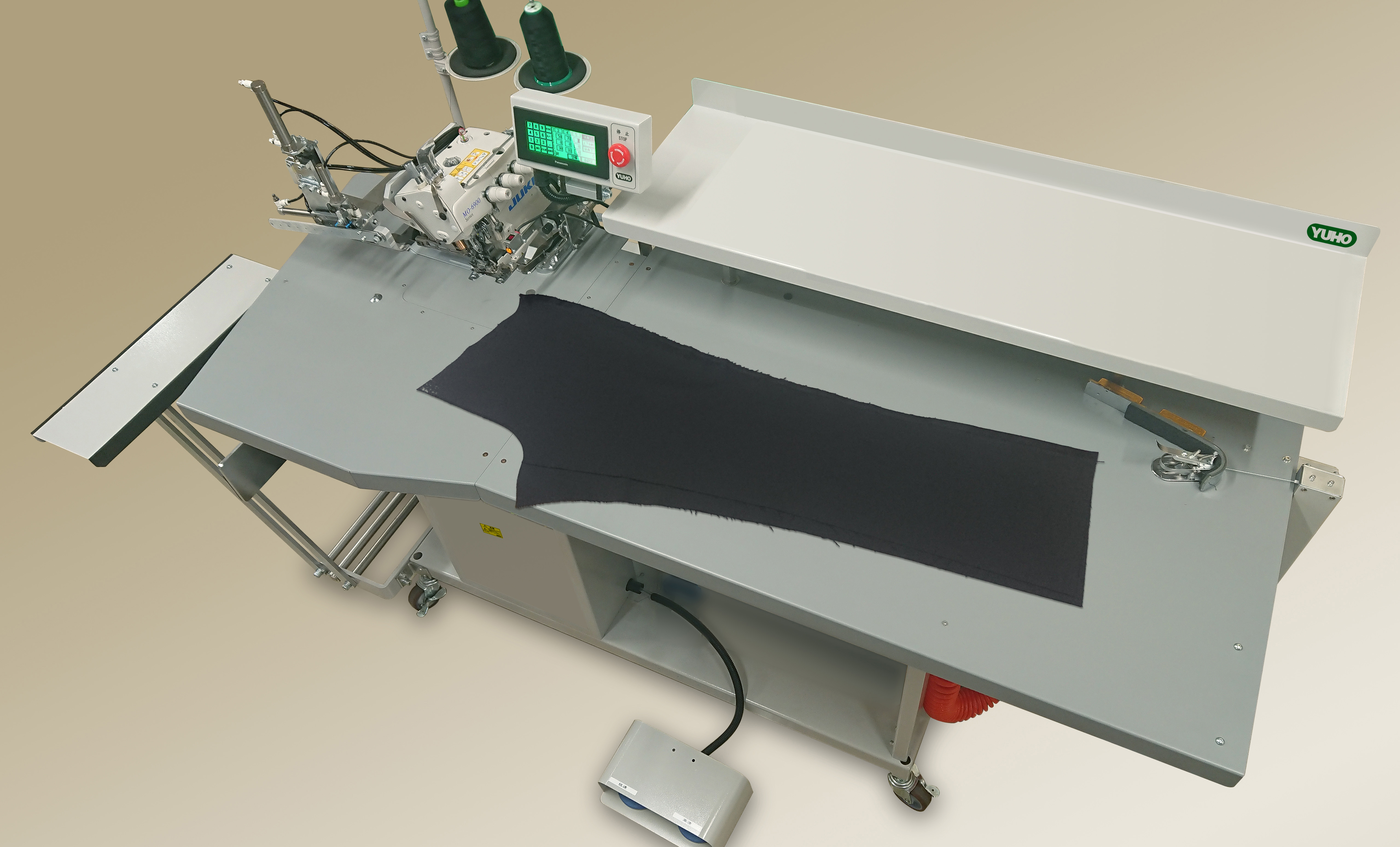

Freedom of making the differentiated shirring amounts zone by zone,

top and bottom, subtlety and delicately, within a seam line.

The latest model of the Safety Stitch Seamer responds to

the demands of garment factories looking for versatile automatic sewing

machines.

Its shirring function is the most brilliant advantage of the U-4309-E,

which features 2 x dedicated stepper motors for each top and bottom-feed dog.

In conjunction with several of YUHO's proprietary mechanisms,

it is an unprecedented and groundbreaking machine that allows

you to freely set subtle and delicate top and bottom shirring and

achieves stable sewing quality and high-efficiency production with simple

operation.

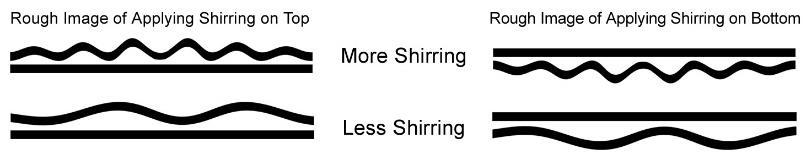

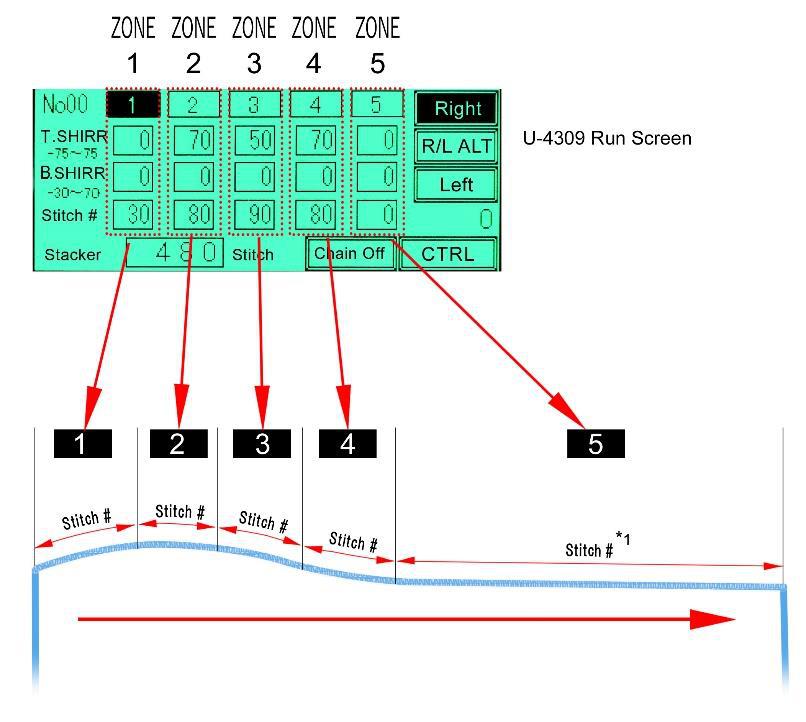

| THE ULTIMATE SHIRRING MACHINE INCORPORATES DEDICATED STEPPER MOTORS FOR EACH TOP BOTTOM FEED DOG | When sewing the front and back bodies of pants together at the side, difference

s in the amount of feeding is made between the top and bottom feed dogs

to create shirring. U-4309-E employs a dedicated stepper motor for each top and bottom feed dog, allowing the user to finely and freely set the top and bottom shirring. In addition, to maximize the sewing head's potential, YUHO has independently fine tuned the top feed dog mechanism. U-4309-E divides a seam line into five zones, making it possible to finely set different amounts of top and bottom feedings individually and delicately in each zone, realizing the differentiated amount of shirring zone by zone. |

@  |

| COVERING WIDE RANGE OF APPLICATIONS | 1. Double chain stitch seamer for side seaming of trousers, shirts, etc. 2. Serging for pants front body with knee lining, etc. 3. Safety stitch seamer for workwear and others. U-4309-E covers three different applications by attaching/detaching needle and knife. Also, when sewing pants front and back body together at the sides, it is no problem to use the materials with knee linings. Note: Depending on the sewing specifications, the sewing head may need to be replaced. |

| YUHO's PROPRIETARY SLIDING EDGE GUIDE | YUHO's unique sliding edge guide mechanism can go behind and retract the

device to standby mode, making the operator's manual work at the beginning

of sewing comfortable. When you press a button on the table, the edge guide moves forward and closes simultaneously as it pinches the edges of the two pieces of fabric. The edge guide automatically releases the materials at the end of sewing and moves back. While sewing a seam line, you can change the edge guide's front or back position as you like. For simple sewing of two pieces together without complicated shirring, you can let it stay in the front position. When inserting materials, because the edge guide opens widely, it is easy to insert them. The edge guide is designed to allow fine adjustments for optimizing it with each fabric depending on the type and thickness of each material. |

| TACTILE OPERATION WITH 2 x FOOT SWITCHES | Incorporating a servo motor, it is possible to precisely set separate sewing speeds for high speed, inching, and low speed. Two foot switches can pause the automatic sequence and perform low speed sewing at the beginning, low speed sewing in the middle, and high speed sewing. Instead of using a switch on the table, it is also possible to set the edge guide to move forward from the back standby position by pressing the foot switch. Mixing cleverly with hands and foot operation, a truly intuitive, easy to understand, and ease of use operating system is completed. |

| MOUSE DEVICE REALIZES OVERLAPPING WORKFLOW | The mouse device keeps holding the edge of the material until the sewing

ends. Consequently, in addition to preventing misalignment of materials, the mouse device frees the operator's hands during stitching. It realizes the overlapping workflow between the current material's sewing process and the following material's preparation process, allowing highly efficient continuous operation. Thanks to the teflon coated table surface and the air feeding functionality, smoother material transportation on the table ensures the operator's hands free operation. |

| FABRIC-END KEEPER | At the end of sewing, as soon as the material is separated from the mouse device and edge guide, the right end of the material is temporarily held by the Fabrick-End Keeper device and transported to the stacker to eliminate misalignment at the end of materials and ensuring the trimming of chain off threads. |

| CLAMP-BAR-TYPE STACKER | After thread trimming, a clamp bar type stacker automatically stacks the

materials, aligning them steadily and neatly. The stacker also supports overlapping workflow since the operator does not need to touch the material once the HIGH (high s peed) foot switch is pressed and the operator releases hands from the material. |

| JUKI MO-6916R SEWING HEAD ONBOARD | U-4309-E is equipped with a high-speed 2-needle safety stitch sewing head

with an excellent bottom and variable top-feed mechanism. This head's improved low vibration, quietness, and reliability characteristics ensure high quality and highly efficient production. The upper feed mechanism has been optimally tuned to bring out the full potential of the sewing head. This dramatically improves work efficiency and makes it possible to perform difficult processes, such as combining different materials, without relying on the operator's skills. |

| AUTO SUCTION OF CHAIN-OFF THREADS | Chain-off threads and cloth chips are automatically sucked, and all are

automatically collected in a dust collection bag, keeping the work environment

clean and dust-free. In addition, U-4309-E is designed with consideration not only for production but also for the overall operation in a garment factory, including maintenance and inspection, such as an air gun that is convenient for cleaning the U-4309-E and casters (with front two-wheel brakes) that make it easy to move. |

| LCD TOUCHSCREEN ENSURES EASY OPERATION | Various operations of onboard devices, such as adjustments, settings, specification changes, etc., can be made by lightly touching the LCD. The touchscreen has an easy-to-use operation system that allows you to perform various settings and adjustments with a single touch, such as switching the edge guide's operation mode and setting the stacker device's operation. Every clothes always requires left and right runstitchings. With U-4309-E, you can select and switch the workflow from three alternatives:"Continuous left," "Continuous right," and "Alternate left/right." When "Alternate left/right" is selected, the left and right operations switch automatically and instantly. In addition, up to 40 sewing patterns can be stored and recalled with a single touch on the LCD touchscreen. |

| CONFIGURATIONS | @ Sliding Edge Guide for Drawing Fabrics @ Two Foot Switches (Slow / Fast) @ Chain-Off Thread/Cloth Chips Auto Suction/Collection System @ Mouse Device (Fabric-End Retainer) @ Stacker (Clamp-Bar Type) @ LCD Touchscreen @ JUKI Limiservo Digital AC Servo Motor @ Stepper Motors dedicated to respective Top- and Bottom-Feed Dog @ Teflon-Coated Table with Air Feeding Functionality @ Air Duster Gun @ 4 x Casters (with brakes: front two wheels) |

|---|